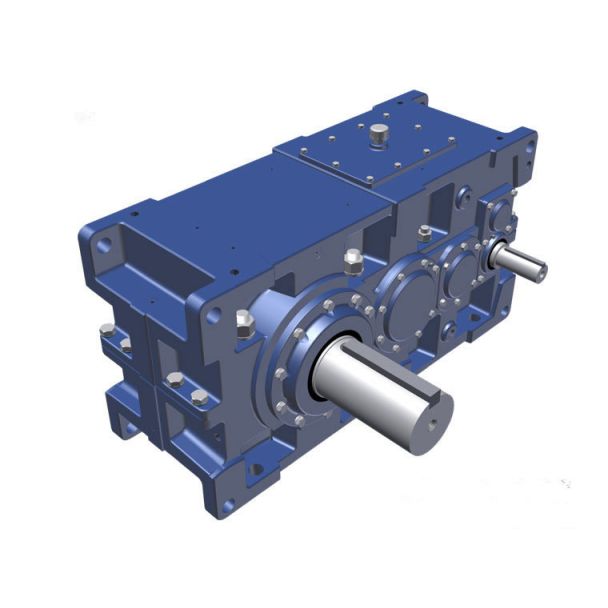

factor f and the peak torque factor f correspondi B2-SV9-B Bevel-helical speed reducers B2

In stock

SKU

B2-SV9-B

$345,000.00

Flender/Flender Gear Units/Bevel-helical speed reducers B2

line with the performance advantages found, this means that system components can be made smaller and thus save on material Furthermore, the amount of refrigerant required is reduced substantially, meaning that the environmental risks of ozone depletion and global warming

Furthermore, the amount of refrigerant required is reduced substantially, meaning that the environmental risks of ozone depletion and global warming  are minimised The influence of the compressor oil used, which is of importance forevaporation, was studied in'depth as function of

are minimised The influence of the compressor oil used, which is of importance forevaporation, was studied in'depth as function of  the oil concentration ~~~~~~ ~~~ ~~~~~ ~ ~ ~~~ ~ ~~ ~~ 2 Duration: 0 0 8 - 3 0

the oil concentration ~~~~~~ ~~~ ~~~~~ ~ ~ ~~~ ~ ~~ ~~ 2 Duration: 0 0 8 - 3 0  9 0ZH8F1 Subject: Collaborative project Reduction of CFC emissions in air-conditioning/ refrigeration Sub-Project Heat transfer on pool'boiling of new refrigerants on single plain and finned tubes Research centre: Laboratorium fur Warme- und Kaltetechnik Universitat - GH - Paderborn Warburger Strasse 1, 3 Paderborn Government sponsorship: DM 3,9 0 Sponsorship ratio: 1% 1. Purpose of the project Within the frameworkof the above sub-project of the DKVjoint research project, heat transfer measurements were conducted during the pool boiling of new refrigerants on three finned tubes with different fin geometries In connection with another sub-project (Wieland-Werke AG), the measurements were intended to - improve the design principles for evaporators with new refrigerants, - illustrate ways of arriving at more compact systems, - facilitate deductions concerning one refrigerant on the basis of another 2. Working steps The heattransfer during pool boilingwas studied on the experimental tubesillustrated in Fig. 1. The left-hand side of Fig. 1 shows scale drawing comparing the fin geometry of the three tubes. One is conventional finned tube, where the veryclose fin spacing is new: it has 3fins per inch, meaning that clear fin spacin of only 0.5 mm results and fin height of just under one millimetre already increases the sur$ce area to roughly three-and--half times that of the plain tube with the same core diameter as the finned tube cp = 3.. Theothertwoareenhanced

9 0ZH8F1 Subject: Collaborative project Reduction of CFC emissions in air-conditioning/ refrigeration Sub-Project Heat transfer on pool'boiling of new refrigerants on single plain and finned tubes Research centre: Laboratorium fur Warme- und Kaltetechnik Universitat - GH - Paderborn Warburger Strasse 1, 3 Paderborn Government sponsorship: DM 3,9 0 Sponsorship ratio: 1% 1. Purpose of the project Within the frameworkof the above sub-project of the DKVjoint research project, heat transfer measurements were conducted during the pool boiling of new refrigerants on three finned tubes with different fin geometries In connection with another sub-project (Wieland-Werke AG), the measurements were intended to - improve the design principles for evaporators with new refrigerants, - illustrate ways of arriving at more compact systems, - facilitate deductions concerning one refrigerant on the basis of another 2. Working steps The heattransfer during pool boilingwas studied on the experimental tubesillustrated in Fig. 1. The left-hand side of Fig. 1 shows scale drawing comparing the fin geometry of the three tubes. One is conventional finned tube, where the veryclose fin spacing is new: it has 3fins per inch, meaning that clear fin spacin of only 0.5 mm results and fin height of just under one millimetre already increases the sur$ce area to roughly three-and--half times that of the plain tube with the same core diameter as the finned tube cp = 3.. Theothertwoareenhanced| Model Type | Bevel-helical speed reducers B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 16100.000000 |

| Ratio Range | 1 : 5…18 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 29900 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender ATB-Loher |

| Country of Manufacture | Yemen |

| Data Sheet & Drawings | factor f and the peak torque factor f correspondi B2-SV9-B Bevel-helical speed reducers B2 |