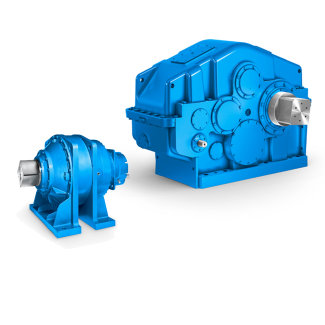

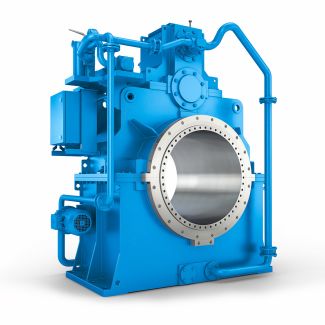

s required Flender GmbH Flender MD Design of B2-SV16A Bevel-helical gear reducers B2

In stock

SKU

B2-SV16A

$13,392.86

Flender/Flender Gear Units/Bevel-helical gear reducers B2

ll the lower docking position, the lantern carriage sh all rest firmly at maintaina ble height from the ground level with the help of stoppers for ease of maintenance. During lowering/raising operation the design sha ll ensure that there is

with the help of stoppers for ease of maintenance. During lowering/raising operation the design sha ll ensure that there is  no damage caused to the mast surface and any ot her parts installed. 4.0 Winch Assembly The winch shall be

no damage caused to the mast surface and any ot her parts installed. 4.0 Winch Assembly The winch shall be  self sustaining and self lubricating type sp ecially designed without the need of breaks, springs or clutches, and shall consist

self sustaining and self lubricating type sp ecially designed without the need of breaks, springs or clutches, and shall consist  of wo drums fabricated from steel with machined grooves and ounted inside the mast at convenient height from the base. The wire rope shall be wound on the drum with one end attached to the lantern carriage while the other end is clamped to the winch drum. The design sh all ensure no inter winding of the fitting ropes. At least four turns of rope shall remain on the drums when the lantern carriage is fully lowered. 4.0 Support Ropes The support ropes shall be of stai nless steel and shall be capa ble of safely handling the lantern carriage load. 4.0 Supply cables. Power supply cables shall be cla ss insulated with required number of cores provided with multi-pin heavy duty locking type male/female connectors the end. Pulley assembly shall accommodate extra cable for emergency supply. Test load shall be of 5-meter length 5-core 2.5-mm2 copper cond uctor cable with multi- pin heavy duty locking type male/female connectors at the ends. Under no circumstances the test lead shall tr avel through the mast. 4.0 Foundation The design and construction of oundation for high mast lighting tower shall be included in the scope of the contractor. The Contractor shall submit the design drawings for approval of MECON for high mast based on soil bearing capacity and wind speed. The Contractor hall be responsible for safe & efficient er ection of the mast. 4.0 Electric Drive & Fittings The drive shall be 3 phase, 4 volt, 5 Hz, class insulated, induct

of wo drums fabricated from steel with machined grooves and ounted inside the mast at convenient height from the base. The wire rope shall be wound on the drum with one end attached to the lantern carriage while the other end is clamped to the winch drum. The design sh all ensure no inter winding of the fitting ropes. At least four turns of rope shall remain on the drums when the lantern carriage is fully lowered. 4.0 Support Ropes The support ropes shall be of stai nless steel and shall be capa ble of safely handling the lantern carriage load. 4.0 Supply cables. Power supply cables shall be cla ss insulated with required number of cores provided with multi-pin heavy duty locking type male/female connectors the end. Pulley assembly shall accommodate extra cable for emergency supply. Test load shall be of 5-meter length 5-core 2.5-mm2 copper cond uctor cable with multi- pin heavy duty locking type male/female connectors at the ends. Under no circumstances the test lead shall tr avel through the mast. 4.0 Foundation The design and construction of oundation for high mast lighting tower shall be included in the scope of the contractor. The Contractor shall submit the design drawings for approval of MECON for high mast based on soil bearing capacity and wind speed. The Contractor hall be responsible for safe & efficient er ection of the mast. 4.0 Electric Drive & Fittings The drive shall be 3 phase, 4 volt, 5 Hz, class insulated, induct| Model Type | Bevel-helical gear reducers B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 625.000000 |

| Ratio Range | 1 : 5.6…20 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 148000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Guss Gmbh & Co. Kg |

| Country of Manufacture | Brunei |

| Data Sheet & Drawings | s required Flender GmbH Flender MD Design of B2-SV16A Bevel-helical gear reducers B2 |