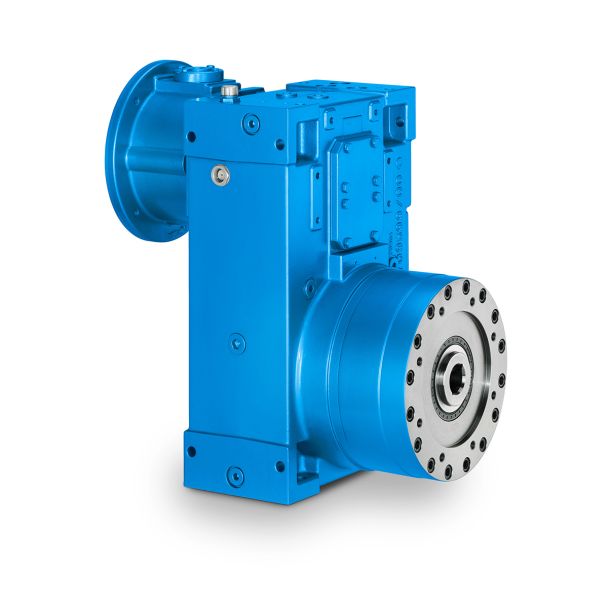

B2-DH-5B t sizes to Threestage gear unit sizes to Ty Bevel-helical gear boxes B2

In stock

SKU

B2-DH-5B

$56,250.00

Flender/Flender Gear Units/Bevel-helical gear boxes B2

n particles. purier comprises two sections (Fig. 2a). There are three decks of sieves in each section. These decks (layers) of sieves in each section oscillate back and forth as result of an eccentric drive. Each layer of sieves has

of sieves in each section oscillate back and forth as result of an eccentric drive. Each layer of sieves has  four individual sieves. The sieves are pro-gressively coarse going from head to the tail end within the layer; however, going

four individual sieves. The sieves are pro-gressively coarse going from head to the tail end within the layer; however, going  fromthe top layer to the bottom, the sieves are progressively ner. To keep the sieve aperturesclean, each sieve has pair

fromthe top layer to the bottom, the sieves are progressively ner. To keep the sieve aperturesclean, each sieve has pair  of guide rails (see Fig. 2c) mounted on the frame under thesieve cloth. brush assembly moves up and down these guide rails, assisted by the oscilla- tion, keeping the underside of the sieve clean. The sieve layers slope slightly downward from head to the tail end. The materials that still remains on top of each of the three layersof sieves are channeled out into three spouts. The material, that falls through all threelayers of sieves to the bottom, is collected altogether into either one of the two shakingchannels provided at the bottom or split into two separate fractions and collected sepa-rately. There are several small aps just above and along the length of the shaking chan- nels. Deecting the aps allows directing the falling material from one channel to the other. The shaking channels act as conveyors in moving the material collected to its outlet. Air is drawn up through the material layers spread over the sieves (see Fig. 2b) to create stratication of the material. Therefore, provision is made to carefully regulatethis air that is being drawn up through the shaking sieves by providing compartmentedhood over the top layer of sieves. This hood is connected to an air trunk providing theaspiration air. Each compartment can be individually regulated to optimize airow across the length and width of the sieve layer. 3.3.4.1 Operation The graded material from sifter enters the purier through feed inlet just ahead of the sieve layers. The feeding device ensures that the material is spread

of guide rails (see Fig. 2c) mounted on the frame under thesieve cloth. brush assembly moves up and down these guide rails, assisted by the oscilla- tion, keeping the underside of the sieve clean. The sieve layers slope slightly downward from head to the tail end. The materials that still remains on top of each of the three layersof sieves are channeled out into three spouts. The material, that falls through all threelayers of sieves to the bottom, is collected altogether into either one of the two shakingchannels provided at the bottom or split into two separate fractions and collected sepa-rately. There are several small aps just above and along the length of the shaking chan- nels. Deecting the aps allows directing the falling material from one channel to the other. The shaking channels act as conveyors in moving the material collected to its outlet. Air is drawn up through the material layers spread over the sieves (see Fig. 2b) to create stratication of the material. Therefore, provision is made to carefully regulatethis air that is being drawn up through the shaking sieves by providing compartmentedhood over the top layer of sieves. This hood is connected to an air trunk providing theaspiration air. Each compartment can be individually regulated to optimize airow across the length and width of the sieve layer. 3.3.4.1 Operation The graded material from sifter enters the purier through feed inlet just ahead of the sieve layers. The feeding device ensures that the material is spread| Model Type | Bevel-helical gear boxes B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 2625.000000 |

| Ratio Range | 1 : 5…18 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 9400 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. FRIEDR. FLENDER AG |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | B2-DH-5B t sizes to Threestage gear unit sizes to Ty Bevel-helical gear boxes B2 |