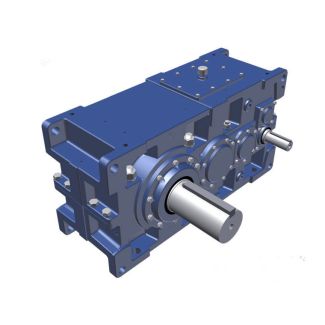

B2-DH-6-A stage gear unit sizes to Fourstage gear unit Bevel-helical speed reduction gearboxes B2

In stock

SKU

B2-DH-6-A

$74,464.29

Flender/Flender Gear Units/Bevel-helical speed reduction gearboxes B2

n provide additional ecological advantages. The continuous dyeing of the running thread enables the dye to be padded-on in cold dyeing liquor, instead of using the absorption process with the dye at boiling temperature over an extended period of time.

dyeing liquor, instead of using the absorption process with the dye at boiling temperature over an extended period of time.  In this process, only 0.3 to 0.4 litres of water are required for 1 kilo- gramme of yarn material. No

In this process, only 0.3 to 0.4 litres of water are required for 1 kilo- gramme of yarn material. No  waste water is generated in this case. In addition to plain dyeing, space dyeing on running thread was also included

waste water is generated in this case. In addition to plain dyeing, space dyeing on running thread was also included  in this project, because the quality demandsand theassociated technical requirementsappeared to be easier to fulfil and because important knowledge for reaching the final goal of plain dyeing could be gathered in this way. Furthermore, the plication options for the use of the results ofthis pro- ject are expanded, as is the interest of otffer segments of the textile industry beyond the dyeing sector. 2. Working steps The functional princi le of the process used to dye the running thread as it is drawn off the undyed cross-wounlbobbin and then wind it up on finished commercial bobbin in continu ous processing cycle can be presented as follows using the concept of test units 2 and 3 The feed bobbins with undyed material are located above the spooler or in separate unwind- ing frame ~~ ~~ ~___-~ ~~ ~ ~~- -~ 4 In the dyeing unit - test unit 2 -the yarn first passes through the liquor padding device,which consists of -shaped dipping tube and the downstream yarn centrifuge. With the help of an electrically driven hollow shaft equipped with centrifuge plate, the yarn, which has been satu- rated with dyein liquor and subsequent1 freed from excess dyeing liquor bythe centrifuging rocess, leaves tile padding device. If adckonal colour effects other than basiccolourare to le obtained, the yarn material is fed at constant speed through program-controlled space dyeing device with 4 spray nozzles for the application of additional dyes, via special thread unwinder and input roll to

in this project, because the quality demandsand theassociated technical requirementsappeared to be easier to fulfil and because important knowledge for reaching the final goal of plain dyeing could be gathered in this way. Furthermore, the plication options for the use of the results ofthis pro- ject are expanded, as is the interest of otffer segments of the textile industry beyond the dyeing sector. 2. Working steps The functional princi le of the process used to dye the running thread as it is drawn off the undyed cross-wounlbobbin and then wind it up on finished commercial bobbin in continu ous processing cycle can be presented as follows using the concept of test units 2 and 3 The feed bobbins with undyed material are located above the spooler or in separate unwind- ing frame ~~ ~~ ~___-~ ~~ ~ ~~- -~ 4 In the dyeing unit - test unit 2 -the yarn first passes through the liquor padding device,which consists of -shaped dipping tube and the downstream yarn centrifuge. With the help of an electrically driven hollow shaft equipped with centrifuge plate, the yarn, which has been satu- rated with dyein liquor and subsequent1 freed from excess dyeing liquor bythe centrifuging rocess, leaves tile padding device. If adckonal colour effects other than basiccolourare to le obtained, the yarn material is fed at constant speed through program-controlled space dyeing device with 4 spray nozzles for the application of additional dyes, via special thread unwinder and input roll to| Model Type | Bevel-helical speed reduction gearboxes B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 3475.000000 |

| Ratio Range | 1 : 6.3…22.4 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 12000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Ges.m.b.H. |

| Country of Manufacture | Jamaica |

| Data Sheet & Drawings | B2-DH-6-A stage gear unit sizes to Fourstage gear unit Bevel-helical speed reduction gearboxes B2 |