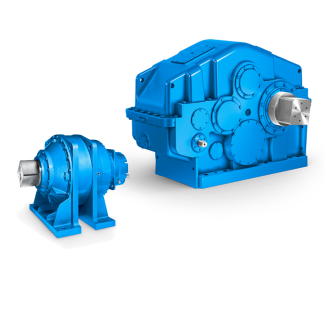

H4HV-28-C envi ronment of the unit Air with little or no sal Helical gear box H4

In stock

SKU

H4HV-28-C

$282,857.14

Flender/Flender Gear Units/Helical gear box H4

ification Report Unique Identifier: 2-1 Revision: 1 Page: 9 of 1 9 Lead times Give method statement of how the contractor will ensure that the lead times will be achieved to ensure that 1 of each gears will be supplied

contractor will ensure that the lead times will be achieved to ensure that 1 of each gears will be supplied  per month. The supplier shall have at least 2 CNC machines to cut and grind gears. 1 Material accuracy Specify

per month. The supplier shall have at least 2 CNC machines to cut and grind gears. 1 Material accuracy Specify  how Chemical/material analysis/composition is done to ensure that the correct material is used before manufacturing 1 NDT Give method statement

how Chemical/material analysis/composition is done to ensure that the correct material is used before manufacturing 1 NDT Give method statement  of how NDT will be done to ensure that there are no cracks before and after rough machining. 1 Hardness verification Give method statement of how material hardness and material microstructure is verified after heat treatment to ensure that the components were hardened to the correct specification. Test samples shall be used as well. Also specify if the hardness verification is done by only the contractor performing the hardness or also by the gear manufacturer. 1 Detailed QCP detailed QCP shall be supplied during tender. This shall be done for each one of the four gears to be manufactured. This shall include the duration between tasks. 1 Sample data pack Supply complete detailed data pack of gear manufactured that has been heat treated, has helical profile, pressure angle of 2 deg, face width of at least 5mm and pitch diameter of at least 1mm. 1 Long lead items Supply list of all long lead items, specifying the duration thereof 1 Gear design software Confirm the Internationally recognised software being used to design and model gear design 4.2 TENDER TECHNICAL EVALUATION The following specifies the technical evaluation during the tender phase. 4.2.1 TENDER EVALAUTION - MANDATORY TECHNICAL REQUIREMENTS Gatekeeper 1: Verifiable references for the following: Valid ISO9certificate for the contractor that will be machining, cutting and grinding the gears. Valid ISO9certificate for the contractor that will be doing the heat treatment. Valid ISO9certificate

of how NDT will be done to ensure that there are no cracks before and after rough machining. 1 Hardness verification Give method statement of how material hardness and material microstructure is verified after heat treatment to ensure that the components were hardened to the correct specification. Test samples shall be used as well. Also specify if the hardness verification is done by only the contractor performing the hardness or also by the gear manufacturer. 1 Detailed QCP detailed QCP shall be supplied during tender. This shall be done for each one of the four gears to be manufactured. This shall include the duration between tasks. 1 Sample data pack Supply complete detailed data pack of gear manufactured that has been heat treated, has helical profile, pressure angle of 2 deg, face width of at least 5mm and pitch diameter of at least 1mm. 1 Long lead items Supply list of all long lead items, specifying the duration thereof 1 Gear design software Confirm the Internationally recognised software being used to design and model gear design 4.2 TENDER TECHNICAL EVALUATION The following specifies the technical evaluation during the tender phase. 4.2.1 TENDER EVALAUTION - MANDATORY TECHNICAL REQUIREMENTS Gatekeeper 1: Verifiable references for the following: Valid ISO9certificate for the contractor that will be machining, cutting and grinding the gears. Valid ISO9certificate for the contractor that will be doing the heat treatment. Valid ISO9certificate| Model Type | Helical gear box H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 13200.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 1400000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Siemens |

| Country of Manufacture | El Salvador |

| Data Sheet & Drawings | H4HV-28-C envi ronment of the unit Air with little or no sal Helical gear box H4 |