H4HH-10-C usher shredder etc Gear units for stirring an Helical gear reducers H4

In stock

SKU

H4HH-10-C

$13,392.86

Flender/Flender Gear Units/Helical gear reducers H4

here there is risk of micro pitting, as is the case for some makes of marine reducers. Product performance Excellent lubricating power. Reduces the friction coefficient under thin film lubrication conditions. Excellent thermal stability and resistance to oxidation. Prevents sludge

lubricating power. Reduces the friction coefficient under thin film lubrication conditions. Excellent thermal stability and resistance to oxidation. Prevents sludge  formation at high temperatures. Excellent anti -corrosion and anti -rust properties in the presence of humidity. High resistance to the

formation at high temperatures. Excellent anti -corrosion and anti -rust properties in the presence of humidity. High resistance to the  formation of foams and water emulsions. Facilitates controlled rolling, preventing the scuffing of gear teeth. Limits the loss of power

formation of foams and water emulsions. Facilitates controlled rolling, preventing the scuffing of gear teeth. Limits the loss of power  due to friction, giving smooth, uniform and silent gear peration. Increases the life of gears by minimizing the presence of oxidation compounds, wear particles and general deposits. Excellent compatibility with seal materials. DIN 5 Part 3 HLP ISO 1 -1 type CKC / CKD AGMA 9 -F1 AntiScuff AIST 2 DAVID BROWN S1.5.1 Type FIVES CINCINNATI -Specs MLLER WEINGARTEN SCHOTTEL (ISO 1 and SIEMENS FLENDER AG Rev. 1 IBERCISA (ISO 2 and CHARACTERISTIC UNITS METHOD CEPSA RADA XMP ISO Grade 6 1 1 2 3 4 Density at 1C Kg/ ASTM -4 0.8 0.8 0.8 0.8 0.9 0.9 Flash Point, COC ASTM -9 2 2 2 2 2 2 Pour Point, max. ASTM -5 -2 -2 -2 -2 -1 -1 Viscosity at 4C cSt ASTM -4 6.1 9.1 1.3 2.5 3.7 4.1 Viscosity at 1C cSt ASTM -4 8.6 1.2 1.7 1.9 2.2 3.2 Viscosity Index - ASTM -2 1 1 9 9 9 9 FZG Scuffing Test, load failure stage - DIN 5 -2 >1 >1 >1 >1 >1 >1 FZG Micro Pitting Test, load failure stage - SAE 5 >1 >1 >1 >1 >1 >1 Copper Corrosion (3h, 1C) - ASTM -1 1B 1B 1B 1B 1B 1B Rust protection - ASTM -6 pass pass pass pass pass pass Material Safety Data Sheet providing information on product hazards, handling precautions, first aid measures, and relevant environmental data is available for this product as per applicable legislation. Marine Lubricants 1 2 3 4 5 6 7 8 9 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 1 Cas

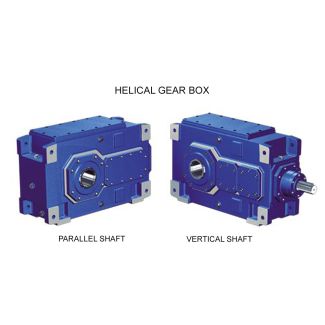

due to friction, giving smooth, uniform and silent gear peration. Increases the life of gears by minimizing the presence of oxidation compounds, wear particles and general deposits. Excellent compatibility with seal materials. DIN 5 Part 3 HLP ISO 1 -1 type CKC / CKD AGMA 9 -F1 AntiScuff AIST 2 DAVID BROWN S1.5.1 Type FIVES CINCINNATI -Specs MLLER WEINGARTEN SCHOTTEL (ISO 1 and SIEMENS FLENDER AG Rev. 1 IBERCISA (ISO 2 and CHARACTERISTIC UNITS METHOD CEPSA RADA XMP ISO Grade 6 1 1 2 3 4 Density at 1C Kg/ ASTM -4 0.8 0.8 0.8 0.8 0.9 0.9 Flash Point, COC ASTM -9 2 2 2 2 2 2 Pour Point, max. ASTM -5 -2 -2 -2 -2 -1 -1 Viscosity at 4C cSt ASTM -4 6.1 9.1 1.3 2.5 3.7 4.1 Viscosity at 1C cSt ASTM -4 8.6 1.2 1.7 1.9 2.2 3.2 Viscosity Index - ASTM -2 1 1 9 9 9 9 FZG Scuffing Test, load failure stage - DIN 5 -2 >1 >1 >1 >1 >1 >1 FZG Micro Pitting Test, load failure stage - SAE 5 >1 >1 >1 >1 >1 >1 Copper Corrosion (3h, 1C) - ASTM -1 1B 1B 1B 1B 1B 1B Rust protection - ASTM -6 pass pass pass pass pass pass Material Safety Data Sheet providing information on product hazards, handling precautions, first aid measures, and relevant environmental data is available for this product as per applicable legislation. Marine Lubricants 1 2 3 4 5 6 7 8 9 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 1 Cas| Model Type | Helical gear reducers H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 625.000000 |

| Ratio Range | 1 : 125…450 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 44200 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Macneill Gears Ltd. |

| Country of Manufacture | France |

| Data Sheet & Drawings | H4HH-10-C usher shredder etc Gear units for stirring an Helical gear reducers H4 |