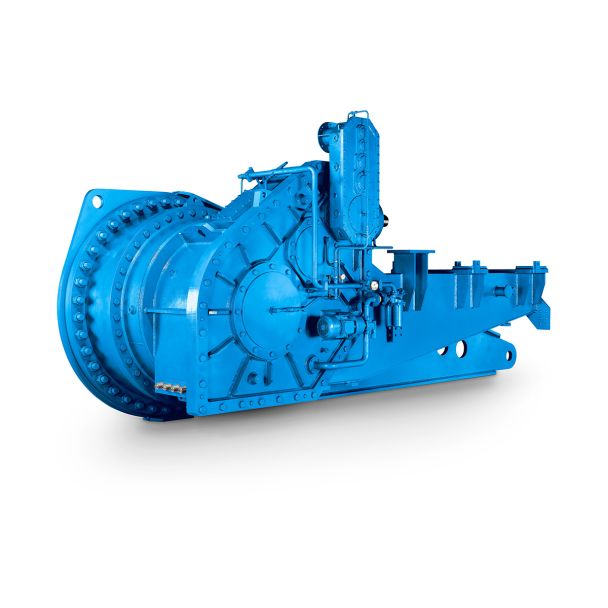

H4-KH-26B equiredPG PGA x f PG Gear unit with dip Helical speed reduction gearbox H4

In stock

SKU

H4-KH-26B

$282,857.14

Flender/Flender Gear Units/Helical speed reduction gearbox H4

ion showing paddy husker and aspirator is shown in Fig. 5. In the husk aspirator, the brown rice and husks are distributed into thin layer and drop into column of air moving with an adjustable velocity. The lighter husks are

are distributed into thin layer and drop into column of air moving with an adjustable velocity. The lighter husks are  thenlifted from the rice. After the husks have been removed, the velocity of the air is decreased, allowing the husks

thenlifted from the rice. After the husks have been removed, the velocity of the air is decreased, allowing the husks  to settle and be collected and removed from the machine. The factors that inuence the performance of the paddy husker

to settle and be collected and removed from the machine. The factors that inuence the performance of the paddy husker  and husk aspirator are as follows: 1. Moisture content of rice. In general, moist paddy does not shell easily. 2. Uniform feeding across the entire length of husking roll. In general, uniform Rice Milling and Processing 3 Fig. 4 Typical mechanism of paddy husker. (Courtesy of Satake Corp.) Fig. 5 Cross section of paddy husker and husk aspirator. (Courtesy of Satake Corp.) 3 Satake feed across the entire length of the husking roll results in longer roll life and less breakage. 3. Speed ratio of husking rolls. It is the difference in peripheral speed of the two rolls that is the driving force behind the husking action. If this differential speedis signicantly reduced, husking efciency will suffer. 4. Husking pressure. Without compression there is no friction to cause each side of the grain to tend to travel at the same speed as its roll. This compressiveforce is essential for husking, but it is also the force that breaks rice and acceler-ates wear of the rubber rolls. 5. Uniformly distributed feed across face of aspirator. Uniform distribution results in uniform air distribution. Thus, there is better aspiration at high capacities, less contamination of husks in the rice stream, and less loss of rice grains with the husk stream. 2.3.2 Paddy Separators Paddy separators are fundamentally density separators. Separation is achieved by - idization, which causes denser brown rice grains to sink to the bottom of bed of rice whereas lighter paddy grains rise to the top. The principle of paddy separation is shown in Fig.

and husk aspirator are as follows: 1. Moisture content of rice. In general, moist paddy does not shell easily. 2. Uniform feeding across the entire length of husking roll. In general, uniform Rice Milling and Processing 3 Fig. 4 Typical mechanism of paddy husker. (Courtesy of Satake Corp.) Fig. 5 Cross section of paddy husker and husk aspirator. (Courtesy of Satake Corp.) 3 Satake feed across the entire length of the husking roll results in longer roll life and less breakage. 3. Speed ratio of husking rolls. It is the difference in peripheral speed of the two rolls that is the driving force behind the husking action. If this differential speedis signicantly reduced, husking efciency will suffer. 4. Husking pressure. Without compression there is no friction to cause each side of the grain to tend to travel at the same speed as its roll. This compressiveforce is essential for husking, but it is also the force that breaks rice and acceler-ates wear of the rubber rolls. 5. Uniformly distributed feed across face of aspirator. Uniform distribution results in uniform air distribution. Thus, there is better aspiration at high capacities, less contamination of husks in the rice stream, and less loss of rice grains with the husk stream. 2.3.2 Paddy Separators Paddy separators are fundamentally density separators. Separation is achieved by - idization, which causes denser brown rice grains to sink to the bottom of bed of rice whereas lighter paddy grains rise to the top. The principle of paddy separation is shown in Fig.| Model Type | Helical speed reduction gearbox H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 13200.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 1030000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | PT Flenindo Aditransimisi |

| Country of Manufacture | Solomon Islands |

| Data Sheet & Drawings | H4-KH-26B equiredPG PGA x f PG Gear unit with dip Helical speed reduction gearbox H4 |