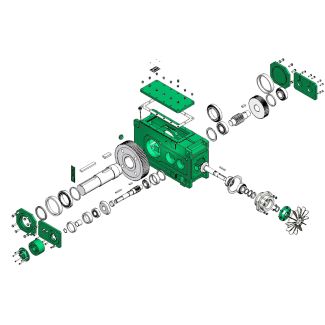

H4-HV10A mounting the drive or for some other purpose For Helical speed reduction gearboxes H4

In stock

SKU

H4-HV10A

$7,821.43

Flender/Flender Gear Units/Helical speed reduction gearboxes H4

iameter. similar principle is said to beapplicable to plain blades for which teeth, according to Ivashko (, are considered to be continuous microscopic chisels that help in smooth digging into the stem for frictional cutting. The shape of these chisels

be continuous microscopic chisels that help in smooth digging into the stem for frictional cutting. The shape of these chisels  depends on the material, heat treatment, and way ofgrinding. The cutting edge becomes blunt once the microscopic chisels are broken.

depends on the material, heat treatment, and way ofgrinding. The cutting edge becomes blunt once the microscopic chisels are broken.  Ivashko ( explained the principal procedure for determining the component distri- bution of the cutting edge and the parameters responsible

Ivashko ( explained the principal procedure for determining the component distri- bution of the cutting edge and the parameters responsible  for shear failure. According tohim, for blade edge making an angle (cutting angle) with the direction of applied force, the cutting force will have two components, normal force /H1Fsin, which pushes the tip of the tooth into the material, making the perforations in it, and tangentialforce, /H1Fcos, which continuously slides the teeth along the material for complete cutting. Cutting is difcult when /H1or 9because in either case, the combinations of utilization of the bottom of the teeth and sliding motion during the process of cuttingare present. For reciprocating-bartype cutter with cutting angle and angle of action (Fig. , the cutting resistance Fcan be expressed as /H1N 1(sin/H1cos/H ( in which the following approximation has been accounted R1/H1R2/H1N1/H1N2 ( Harvesting and Threshing 6 Fig. 5 Blade edge conguration and resistance to cutting. (From Ref. 2.) where, R1,R2/H1frictional resistances, N1,N2/H1normal reactions, /H1coefcient of friction between the blade and material. Ifis the angle of wedge, then its relation with other angles will be tan/H1tantan ( Under the condition that N1andare constants, the force required to cut straw is proportional to the angle of action, . Hence, for the xed value of , minimum cutting force would be required either by decreasing the angle of wedge or cutting angle . 2.3 Cutting Force and Energy Comparative performance of cutting elements used in harvester design can be judged by their cutting

for shear failure. According tohim, for blade edge making an angle (cutting angle) with the direction of applied force, the cutting force will have two components, normal force /H1Fsin, which pushes the tip of the tooth into the material, making the perforations in it, and tangentialforce, /H1Fcos, which continuously slides the teeth along the material for complete cutting. Cutting is difcult when /H1or 9because in either case, the combinations of utilization of the bottom of the teeth and sliding motion during the process of cuttingare present. For reciprocating-bartype cutter with cutting angle and angle of action (Fig. , the cutting resistance Fcan be expressed as /H1N 1(sin/H1cos/H ( in which the following approximation has been accounted R1/H1R2/H1N1/H1N2 ( Harvesting and Threshing 6 Fig. 5 Blade edge conguration and resistance to cutting. (From Ref. 2.) where, R1,R2/H1frictional resistances, N1,N2/H1normal reactions, /H1coefcient of friction between the blade and material. Ifis the angle of wedge, then its relation with other angles will be tan/H1tantan ( Under the condition that N1andare constants, the force required to cut straw is proportional to the angle of action, . Hence, for the xed value of , minimum cutting force would be required either by decreasing the angle of wedge or cutting angle . 2.3 Cutting Force and Energy Comparative performance of cutting elements used in harvester design can be judged by their cutting| Model Type | Helical speed reduction gearboxes H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 365.000000 |

| Ratio Range | 1 : 125…450 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 44200 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender de Colombia |

| Country of Manufacture | South Korea |

| Data Sheet & Drawings | H4-HV10A mounting the drive or for some other purpose For Helical speed reduction gearboxes H4 |