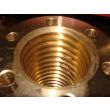

H4-HV-13-A Introduction Notes Information about basics Overvi Helical gear reducers H4

In stock

SKU

H4-HV-13-A

$18,750.00

Flender/Flender Gear Units/Helical gear reducers H4

ic, aliphatic basis (so-called cold cleaners) or similar materialsor preparations,whichareallratedas highlyflammableaccordingtoAII orAlll and which represent potential danger to wastewater. In contrast, an aqueous system can be treated in-house and disposed of in wastewater plants according to the current state of

contrast, an aqueous system can be treated in-house and disposed of in wastewater plants according to the current state of  the art. ' 2. Working steps The formulations for aqueous degreasing must fulfil the following requirements - Metal compatibility similar

the art. ' 2. Working steps The formulations for aqueous degreasing must fulfil the following requirements - Metal compatibility similar  to CHCs - Degreasing potential and fat absorption capacity similar to CHCs, and corresponding grease/oil demulsifying properties - Attainment of

to CHCs - Degreasing potential and fat absorption capacity similar to CHCs, and corresponding grease/oil demulsifying properties - Attainment of  residual chemical values within legal specifications In contrast to CHCdegreasin , metallic materials can show surface imperfections due tocorro- sion or changes in the crystal?ne structure following aqueous treatment and the drying subse- quently required Aqueous cleaning systems can be used overwide pH ranges, but preferably in the range from neutral to strongly alkaline Corresponding1 the effect of the cleaning medium on the metal surface must be considered discriminating$ The following areformula- tion aids and requirements: - Theoretical observations of interfacial tensions on hard surfaces - Properties of oils, greases and auxiliary metal-working agents which predominate in the metal-working industry in terms of quantity 2 - Development of demulsifying properties which can be effectively put to use in industrial - Corrosion protection measures and tests according to recognised standards practice 3. Results Suitable surfactant combinations with which metal surfaces can be degreased and cleaned were sought on the basis of practical specifications. They were combined into new formula- tions with special components to meet the various demands, .. for temporary corrosion pro- tection of Fe materials. Surfactants and other com onents had to be matched to each other in sucha waythat dissolved greasesand oils can begmulsifiedandseparated from thecleaning

residual chemical values within legal specifications In contrast to CHCdegreasin , metallic materials can show surface imperfections due tocorro- sion or changes in the crystal?ne structure following aqueous treatment and the drying subse- quently required Aqueous cleaning systems can be used overwide pH ranges, but preferably in the range from neutral to strongly alkaline Corresponding1 the effect of the cleaning medium on the metal surface must be considered discriminating$ The following areformula- tion aids and requirements: - Theoretical observations of interfacial tensions on hard surfaces - Properties of oils, greases and auxiliary metal-working agents which predominate in the metal-working industry in terms of quantity 2 - Development of demulsifying properties which can be effectively put to use in industrial - Corrosion protection measures and tests according to recognised standards practice 3. Results Suitable surfactant combinations with which metal surfaces can be degreased and cleaned were sought on the basis of practical specifications. They were combined into new formula- tions with special components to meet the various demands, .. for temporary corrosion pro- tection of Fe materials. Surfactants and other com onents had to be matched to each other in sucha waythat dissolved greasesand oils can begmulsifiedandseparated from thecleaning| Model Type | Helical gear reducers H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 875.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 90700 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Siemens Industriegetriebe GmbH |

| Country of Manufacture | Turkmenistan |

| Data Sheet & Drawings | H4-HV-13-A Introduction Notes Information about basics Overvi Helical gear reducers H4 |