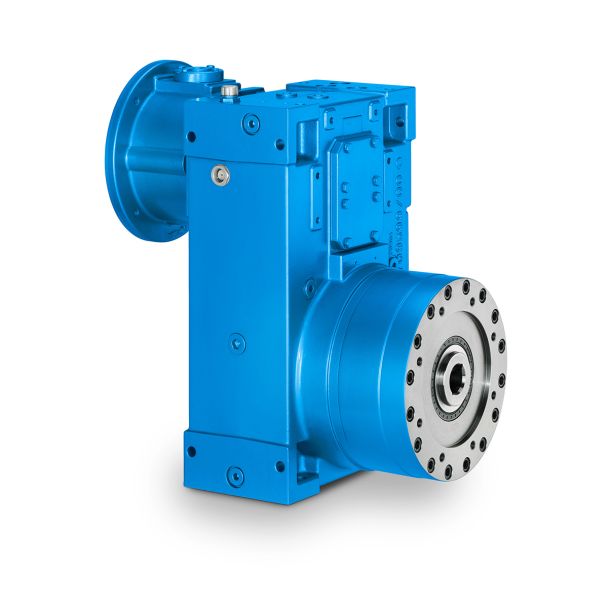

H4-HH-12-D years of experience in the applications ensure max Helical speed reduction gearbox H4

In stock

SKU

H4-HH-12-D

$21,857.14

Flender/Flender Gear Units/Helical speed reduction gearbox H4

hich has the following characteristics: Friction coefficient "" = 0.0 Resistant to pressure up to maximum pressure of 3 /mm2 Ageing resistant 5 / 9BA 5 en 0/2Table 1: Recommended lubricants for shrink disks after their cleaning Lubricant Form Manufacturer

Ageing resistant 5 / 9BA 5 en 0/2Table 1: Recommended lubricants for shrink disks after their cleaning Lubricant Form Manufacturer  Molykote Rapid Spray or paste DOW Corning Aemasol MO 1 Spray or paste . . Matthes Unimoly 5 Powder Klber

Molykote Rapid Spray or paste DOW Corning Aemasol MO 1 Spray or paste . . Matthes Unimoly 5 Powder Klber  Lubrication gleitmo 1 Spray or paste Fuchs Lubritec Other lubricants may be used; however they must have the same characteristics.

Lubrication gleitmo 1 Spray or paste Fuchs Lubritec Other lubricants may be used; however they must have the same characteristics.  Join the inner ring ( and the outer ring (. Place the tensioning bolts and screw in some threads by hand. 6.7.3.4 Re-fitting the shrink disk Note The procedure described in item 6.7.3.1 must be observed for refitting the shrink disk. 6.7.3.5 Inspection of the shrink disk Note In all cases the examination of the shrink disk should be carried out simultaneously with the examination of the gear unit, however at least every 1 months. Inspection of the shrink disk is limited to visual assessment of its condition. The following must be observed when carrying out this work: Loose bolts Damage caused by force Flush position of the inner ring ( in relation to the outer ring ( 6.7.4 Demounting If frictional corrosion has occurred on the seating surfaces, rust-releasing agent may be used to facilitate forcing off the gear unit. The rust releaser can be injected through the pressurised oil connection (see figure by means of pump. The end plate and the locking ring must first be removed. When the rust-releasing agent has taken sufficient effect, pull the gear unit off with the device (see figure 3 and/or figure . Removing the gear unit from the driven-machine shaft can be done, depending on local possibilities, as follows: preferably using hydraulic lifting device (see figure , or using forcing screws in an end plate (see figure or using central threaded spindle. 5 / 9BA 5 en 0/2 Fig. 3: Hollow shaft in shrink disk design, demounting with hydraulic lifti

Join the inner ring ( and the outer ring (. Place the tensioning bolts and screw in some threads by hand. 6.7.3.4 Re-fitting the shrink disk Note The procedure described in item 6.7.3.1 must be observed for refitting the shrink disk. 6.7.3.5 Inspection of the shrink disk Note In all cases the examination of the shrink disk should be carried out simultaneously with the examination of the gear unit, however at least every 1 months. Inspection of the shrink disk is limited to visual assessment of its condition. The following must be observed when carrying out this work: Loose bolts Damage caused by force Flush position of the inner ring ( in relation to the outer ring ( 6.7.4 Demounting If frictional corrosion has occurred on the seating surfaces, rust-releasing agent may be used to facilitate forcing off the gear unit. The rust releaser can be injected through the pressurised oil connection (see figure by means of pump. The end plate and the locking ring must first be removed. When the rust-releasing agent has taken sufficient effect, pull the gear unit off with the device (see figure 3 and/or figure . Removing the gear unit from the driven-machine shaft can be done, depending on local possibilities, as follows: preferably using hydraulic lifting device (see figure , or using forcing screws in an end plate (see figure or using central threaded spindle. 5 / 9BA 5 en 0/2 Fig. 3: Hollow shaft in shrink disk design, demounting with hydraulic lifti| Model Type | Helical speed reduction gearbox H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 1020.000000 |

| Ratio Range | 1 : 125…450 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 78000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. Friedr. Flender AG & Co. KG |

| Country of Manufacture | Guatemala |

| Data Sheet & Drawings | H4-HH-12-D years of experience in the applications ensure max Helical speed reduction gearbox H4 |