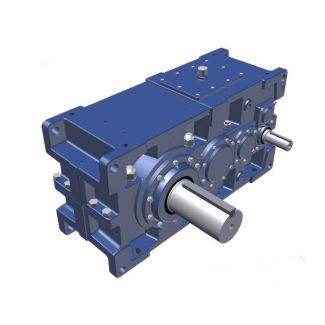

H4-HH13-B ender gear units are used Noise behavior The noi Helical gear units H4

In stock

SKU

H4-HH13-B

$30,000.00

Flender/Flender Gear Units/Helical gear units H4

hicle (Fig. (Ashby, . Intermodal containers use recessed-type systems, in which the entire refrigeration unit is fused to the front section of the container so that the containers arethe same length as nonrefrigerated containers and can therefore be stacked on

section of the container so that the containers arethe same length as nonrefrigerated containers and can therefore be stacked on  atcars orcontainer ships (Fig. (Ashby, . Transportation and Handling 5 Fig. 3 Nose-mounted refrigeration system used in semitrailer. 3.2.2 Ice

atcars orcontainer ships (Fig. (Ashby, . Transportation and Handling 5 Fig. 3 Nose-mounted refrigeration system used in semitrailer. 3.2.2 Ice  Cooling Ice cooling is the oldest and simplest cooling method. Ice is good heat absorber, having latent heat of fusion

Cooling Ice cooling is the oldest and simplest cooling method. Ice is good heat absorber, having latent heat of fusion  of 3 kJ kg/H1(1 Btu lb/H. In addition to providing cool environment for horticultural produce, it maintains high humidity levels within the trans-port vehicle. It can be used as the main cooling source or as supplement to mechanicalrefrigeration systems. In the latter case, ice cooling provides protection for the produceif the mechanical refrigeration unit fails or its capacity is not sufcient to cool the produceto the desired temperature. Ice cooling is used in land and air transport. Finely crushed ice, aked-ice, or liquid ice (slurry of ice and water) can be blown onto the top of the produce. This process is known as top-icing . Crushed ice or liquid ice can also be applied on the top of individual pallets or injected into individual boxes (pack- age icing) before loading. Package icing can also be used as precooling method. Highlyperishable produce such as broccoli and sweet corn are commonly precooled with liquidice. The remaining ice particles within packages serve to protect the produce from rewarm- ing and dehydration during transport. Compared to other cooling methods, ice cooling is the only method that provides thermal and humidity protection. Nevertheless, it can only be used for produce that cantolerate high levels of humidity because fruits and vegetables may decay as result ofexcess moisture. Welby and McGregor ( and Ashby ( have prepared list ofproduce that can be top- or package-iced. Packaging materials for prod

of 3 kJ kg/H1(1 Btu lb/H. In addition to providing cool environment for horticultural produce, it maintains high humidity levels within the trans-port vehicle. It can be used as the main cooling source or as supplement to mechanicalrefrigeration systems. In the latter case, ice cooling provides protection for the produceif the mechanical refrigeration unit fails or its capacity is not sufcient to cool the produceto the desired temperature. Ice cooling is used in land and air transport. Finely crushed ice, aked-ice, or liquid ice (slurry of ice and water) can be blown onto the top of the produce. This process is known as top-icing . Crushed ice or liquid ice can also be applied on the top of individual pallets or injected into individual boxes (pack- age icing) before loading. Package icing can also be used as precooling method. Highlyperishable produce such as broccoli and sweet corn are commonly precooled with liquidice. The remaining ice particles within packages serve to protect the produce from rewarm- ing and dehydration during transport. Compared to other cooling methods, ice cooling is the only method that provides thermal and humidity protection. Nevertheless, it can only be used for produce that cantolerate high levels of humidity because fruits and vegetables may decay as result ofexcess moisture. Welby and McGregor ( and Ashby ( have prepared list ofproduce that can be top- or package-iced. Packaging materials for prod| Model Type | Helical gear units H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 1400.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 90700 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | FLENDER ZAHNRADGETRIEBE |

| Country of Manufacture | Haiti |

| Data Sheet & Drawings | H4-HH13-B ender gear units are used Noise behavior The noi Helical gear units H4 |