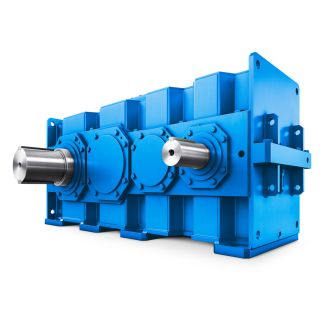

Helical gearboxes H4 Sugar beet washing machines sugar beet cutters H4-FV24A

In stock

SKU

H4-FV24A

$173,571.43

Flender/Flender Gear Units/Helical gearboxes H4

lant operating according to the semi-dry process, as well as grate preheater plant operating according to the semi-wet process Ammonia water was used as the reducing ent The advantage is that the safety arrange- water is stored in rented container

water was used as the reducing ent The advantage is that the safety arrange- water is stored in rented container  tank and distributed as evenly as possible across the gas cross-section via several water-cooled probes with nozzles at gas tem

tank and distributed as evenly as possible across the gas cross-section via several water-cooled probes with nozzles at gas tem  eratures of between 8 and 1 " Depending on the design of the preheater, consideraheadaptation work is sometimes necessary in

eratures of between 8 and 1 " Depending on the design of the preheater, consideraheadaptation work is sometimes necessary in  this context For this reason, the NH3 feed device for every kiln plant must be tested in preliminary trials The actual trial then lasts three to four weeks, including assembly and disassembly work ments for the trials are not so extensive and, erefore, also not too expensive The ammonia 3. Results In order to arrive at universally valid statements on how the NO, emissions from cement kiln plants can be cut by non-catalytic NO reduction through the addition of NH3, 1 trials were performed on 3 kiln plants with cyclone preheaters and 2 kiln plants with grate preheaters With an NH3/N0 molar ratio of 1, some 1 to 7% of the NO mass flow in the kiln exhaust gas was degraded The level of NO degradation mainly depended on the reaction temperature at the oint of addition, which was fre uently defined within very narrow limits by the design of the Filn plant It could only be sligh% influenced in the case of kiln plants with cyclone pre- 1 heaters by means of appropriate selection of the point of addition for the NH, water. However, the CO concentration occasionally increased considerably with this pe of plant due to the high OH radical requirement of the degradation reaction when the riln was operated with dispersible fuel in the secondary furnace for precalcining. NH, loss occurred if the reaction temperatures were below about 9 'Cor the NO concentra- tions and, thus, the NH3/N0 molar ratio fluctuated intensel The extent to which such fluctua- tions can

this context For this reason, the NH3 feed device for every kiln plant must be tested in preliminary trials The actual trial then lasts three to four weeks, including assembly and disassembly work ments for the trials are not so extensive and, erefore, also not too expensive The ammonia 3. Results In order to arrive at universally valid statements on how the NO, emissions from cement kiln plants can be cut by non-catalytic NO reduction through the addition of NH3, 1 trials were performed on 3 kiln plants with cyclone preheaters and 2 kiln plants with grate preheaters With an NH3/N0 molar ratio of 1, some 1 to 7% of the NO mass flow in the kiln exhaust gas was degraded The level of NO degradation mainly depended on the reaction temperature at the oint of addition, which was fre uently defined within very narrow limits by the design of the Filn plant It could only be sligh% influenced in the case of kiln plants with cyclone pre- 1 heaters by means of appropriate selection of the point of addition for the NH, water. However, the CO concentration occasionally increased considerably with this pe of plant due to the high OH radical requirement of the degradation reaction when the riln was operated with dispersible fuel in the secondary furnace for precalcining. NH, loss occurred if the reaction temperatures were below about 9 'Cor the NO concentra- tions and, thus, the NH3/N0 molar ratio fluctuated intensel The extent to which such fluctua- tions can| Model Type | Helical gearboxes H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 8100.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 725000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | FLENDER GUSS GMBH |

| Country of Manufacture | Guyana |

| Data Sheet & Drawings | Helical gearboxes H4 Sugar beet washing machines sugar beet cutters H4-FV24A |