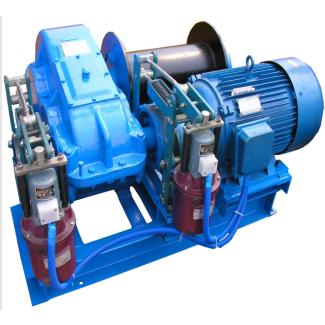

Helical gear reducers H4 kW see page f Gear unit with auxiliary co H4-FV-7-A

In stock

SKU

H4-FV-7-A

$486,428.57

Flender/Flender Gear Units/Helical gear reducers H4

Krenzer, .: CNC Bevel gear generators and ared cup formate gear grinding. AGMA Technical Paper 9 FTM 1 ( [KRUM4] Krumme, .: Klingelnberg Palloid-Spiralkegelra der. Verlag Julius Springer, Berlin ( [LIER0] Lierse, .: Abrichten von Schleifwerkzeugen fu die Verzahnungsbearbeitung. Seminar:

Krumme, .: Klingelnberg Palloid-Spiralkegelra der. Verlag Julius Springer, Berlin ( [LIER0] Lierse, .: Abrichten von Schleifwerkzeugen fu die Verzahnungsbearbeitung. Seminar:  Feinbearbeitung von Stirnra dern in Serie 3./4.1.2 Aachen [PRRE6] Preuger, .; Reindl, .: Technisches Hilfsbuch Klingelnberg, 1. Auage Verlag Julius

Feinbearbeitung von Stirnra dern in Serie 3./4.1.2 Aachen [PRRE6] Preuger, .; Reindl, .: Technisches Hilfsbuch Klingelnberg, 1. Auage Verlag Julius  Springer, Berlin [SIZ0] Stahl-Informations-Zentrum: Merkblatt 4, Postfach 1 4 4, 4 Dusseldorf ( [STAD9] Stadtfeld, .., Kotthaus, .: Das kontinuierliche

Springer, Berlin [SIZ0] Stahl-Informations-Zentrum: Merkblatt 4, Postfach 1 4 4, 4 Dusseldorf ( [STAD9] Stadtfeld, .., Kotthaus, .: Das kontinuierliche  Schleifen geha rteter Kegelra der mit bogenfo rmiger Flankenlinie. In: Bartz, .. (Hrsg.): Kegelrad- getriebe. 1. Au., . 1. Expert, Ehningen ( [TUER0] Tu rich, .: Werkzeug-Prolerzeugung fu das Verzahnungsschleifen. Disser- tation, Universita Hannover ( [WEIS9] Weissohn, ..: Die Technik der -Pegel-Regelung, HTM 4 ( [WESS0] Wessels, .: Analyse des Abrichtprozesses von Korund-Topfscheiben fu das Kegelradschleifen. 4. Arbeitsstagung Zahnrad- und Getriebeunter-suchungen WZL, Aachen 2./2.0.2 [WINT1] Winterthur Technology Group: Precision Grinding Wheels, 2 Catalogue, Winterthur Schleiftechnik AG, Winterthur, Switzerland ( [WUEN6] Wu ning, .: Weiterentwicklung der Gasaufkohlungstechnik, HTM 2 ( [WYSS9] Wyss, .: Regelung des Ha rteverlaufs in der aufgekohlten Werkstu ck- Randschicht, HTM 5 (2 6 Manufacturing Process Chapter 7 Quality Assurance 7.1 Measurement and Correction 7.1.1 Measuring Tasks Two tasks are foremost when testing bevel and hypoid gears. The rst is to assure the quality specications of the production job in the certication framework according to the regulations laid down in ISO 9 ff. and ISO 1 ff. Thistask is becoming increasingly important for the manufacturer, as the regulationsstipulate that the quality of the products must be documented on continuous basis.This means that measurements must be made much more frequently than has beenthe case in recent year

Schleifen geha rteter Kegelra der mit bogenfo rmiger Flankenlinie. In: Bartz, .. (Hrsg.): Kegelrad- getriebe. 1. Au., . 1. Expert, Ehningen ( [TUER0] Tu rich, .: Werkzeug-Prolerzeugung fu das Verzahnungsschleifen. Disser- tation, Universita Hannover ( [WEIS9] Weissohn, ..: Die Technik der -Pegel-Regelung, HTM 4 ( [WESS0] Wessels, .: Analyse des Abrichtprozesses von Korund-Topfscheiben fu das Kegelradschleifen. 4. Arbeitsstagung Zahnrad- und Getriebeunter-suchungen WZL, Aachen 2./2.0.2 [WINT1] Winterthur Technology Group: Precision Grinding Wheels, 2 Catalogue, Winterthur Schleiftechnik AG, Winterthur, Switzerland ( [WUEN6] Wu ning, .: Weiterentwicklung der Gasaufkohlungstechnik, HTM 2 ( [WYSS9] Wyss, .: Regelung des Ha rteverlaufs in der aufgekohlten Werkstu ck- Randschicht, HTM 5 (2 6 Manufacturing Process Chapter 7 Quality Assurance 7.1 Measurement and Correction 7.1.1 Measuring Tasks Two tasks are foremost when testing bevel and hypoid gears. The rst is to assure the quality specications of the production job in the certication framework according to the regulations laid down in ISO 9 ff. and ISO 1 ff. Thistask is becoming increasingly important for the manufacturer, as the regulationsstipulate that the quality of the products must be documented on continuous basis.This means that measurements must be made much more frequently than has beenthe case in recent year| Model Type | Helical gear reducers H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 22700.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 21700 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Ltd., China |

| Country of Manufacture | Uzbekistan |

| Data Sheet & Drawings | Helical gear reducers H4 kW see page f Gear unit with auxiliary co H4-FV-7-A |