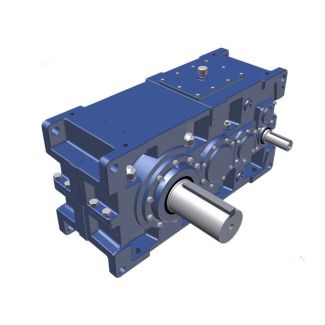

H4-DH-22B tion site code Order no position serial no year o Helical gear boxes H4

In stock

SKU

H4-DH-22B

$173,571.43

Flender/Flender Gear Units/Helical gear boxes H4

in precooling. Hortic. Technol. 2(: 4. 5. CH Crisosto. 1. Sweet cherry harvesting, postharvest handling and storage. In: Perishables Handling. University of California 7: 2. 5. MT Talbot, SA Sargent, and JK Brecht. 1. Cooling Florida Sweet Corn. Florida Extension

University of California 7: 2. 5. MT Talbot, SA Sargent, and JK Brecht. 1. Cooling Florida Sweet Corn. Florida Extension  Service, University of Florida, Circular 9. Packaging of Fruits and Vegetables JAMES . SMITH, HOSAHALLI . RAMASWAMY, and . .

Service, University of Florida, Circular 9. Packaging of Fruits and Vegetables JAMES . SMITH, HOSAHALLI . RAMASWAMY, and . .  VIJAYA RAGHAVAN McGill University, Sainte-Anne-de-Bellevue, Quebec, Canada BYRAPPA RANGANNA University of Agricultural Sciences, Bangalore, India 1 INTRODUCTION The postharvest losses

VIJAYA RAGHAVAN McGill University, Sainte-Anne-de-Bellevue, Quebec, Canada BYRAPPA RANGANNA University of Agricultural Sciences, Bangalore, India 1 INTRODUCTION The postharvest losses  of important commercial fruits and vegetables vary from 2% to 5% before they reach consumers. Fruits and vegetables are high in moisture, ranging from 7% to 9%. Their equilibrium humidities are as high as 9%. Under normal atmosphericconditions they dry rapidly, which causes wilting and shriveling as result of loss ofrigidity and shrinkage of cells. The primary objective of packaging of fruits and vegetablesis to protect the contents during storage, transportation and distribution against deteriora-tion, which may be physical, chemical, or biological. Packaging is hence provided at the point of production or processing or at distribution centers. Though packaging forms the last link in the chain of production, storage, marketing, and distribution, it still plays animportant role in delivering the contents safe from the farm gate to the consumer plate.Increase in production can have an impact on the consumer only when the food is whole-some, unadulterated, and available under hygienic conditions at an economical price. Asmentioned, about 2% to 4% of fruits and vegetables are spoiled or become substandardduring storage and distribution. This enormous wastage, which results in product scarcity and higher prices, is attributed mainly to poor packaging, improper handling methods, and inadequate transportation facilities. Robertson ( denes packaging as the enclosure of products, items or pack- ages in w

of important commercial fruits and vegetables vary from 2% to 5% before they reach consumers. Fruits and vegetables are high in moisture, ranging from 7% to 9%. Their equilibrium humidities are as high as 9%. Under normal atmosphericconditions they dry rapidly, which causes wilting and shriveling as result of loss ofrigidity and shrinkage of cells. The primary objective of packaging of fruits and vegetablesis to protect the contents during storage, transportation and distribution against deteriora-tion, which may be physical, chemical, or biological. Packaging is hence provided at the point of production or processing or at distribution centers. Though packaging forms the last link in the chain of production, storage, marketing, and distribution, it still plays animportant role in delivering the contents safe from the farm gate to the consumer plate.Increase in production can have an impact on the consumer only when the food is whole-some, unadulterated, and available under hygienic conditions at an economical price. Asmentioned, about 2% to 4% of fruits and vegetables are spoiled or become substandardduring storage and distribution. This enormous wastage, which results in product scarcity and higher prices, is attributed mainly to poor packaging, improper handling methods, and inadequate transportation facilities. Robertson ( denes packaging as the enclosure of products, items or pack- ages in w| Model Type | Helical gear boxes H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 8100.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 470000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Power Transmission Inc. |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | H4-DH-22B tion site code Order no position serial no year o Helical gear boxes H4 |