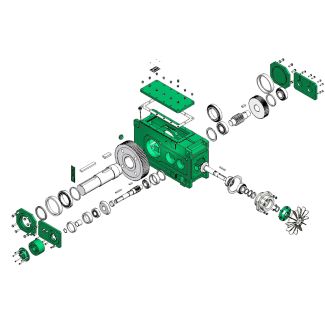

H4-CV-27-A multistage gear units up to the torque Nm are l Helical gear box H4

In stock

SKU

H4-CV-27-A

$254,571.43

Flender/Flender Gear Units/Helical gear box H4

he relative offset relin selected rear axle drives of passenger cars2 5 Noise Behavior Whole Depth The whole depth is calculated as the sum of the addendum and dedendum. The difference between the pinion addendum and wheel dedendum, rectied to

calculated as the sum of the addendum and dedendum. The difference between the pinion addendum and wheel dedendum, rectied to  allow for prole shift, is the clearance. Owing to the desired magnitude of the tooth root radius or to the

allow for prole shift, is the clearance. Owing to the desired magnitude of the tooth root radius or to the  curved tooth root shape induced by tilting of the tool, the distance between the tip and root must be at

curved tooth root shape induced by tilting of the tool, the distance between the tip and root must be at  least 0.2.3 mnin order to prevent interference. The whole depth is therefore usually 2.2.3 mn(cf. Sect. 3.. Larger whole depth factors increase the lever arm of the point at which the force is applied and, hence, the bending moment on the tooth; smaller whole depth factors increase contact pressure because the tooth ank area diminishes. To increase the contact ratio when the space for installing the gears is limited, the whole depth can be made larger than recommended using standard factors. Gears whose whole depth is enlarged in this way are referred to collectively as high prole gears. Different whole depth factors are chosen to allow reworking of the anks. Work pieces can be reworked if the clearance in the basic design is sufciently large. Reworking of the pinion or wheel reduces the thickness of the tooth. The resulting larger backlash is compensated by reducing the installed distances, and functioning gear set is still obtained. Different addendum and dedendum factors are used for different vehicle gear systems. Figure 5.1 shows the extent to which these design strategies differ, using the 1 rear axle gear sets from Fig. 5.1 as examples. Fig. 5.1 Total contact ratio as function of the sum of pinion and wheel tooth numbers Fig. 5.1 Total contact ratio of sample gears as function of the sum of pinion and wheel tooth numbers5.2 Noise Excitation by Means of Gear Tooth Design 2 Spiral Angle The spiral angle is frequently used to alter the ratio between the axial and radial tooth forces. The spiral angle is als

least 0.2.3 mnin order to prevent interference. The whole depth is therefore usually 2.2.3 mn(cf. Sect. 3.. Larger whole depth factors increase the lever arm of the point at which the force is applied and, hence, the bending moment on the tooth; smaller whole depth factors increase contact pressure because the tooth ank area diminishes. To increase the contact ratio when the space for installing the gears is limited, the whole depth can be made larger than recommended using standard factors. Gears whose whole depth is enlarged in this way are referred to collectively as high prole gears. Different whole depth factors are chosen to allow reworking of the anks. Work pieces can be reworked if the clearance in the basic design is sufciently large. Reworking of the pinion or wheel reduces the thickness of the tooth. The resulting larger backlash is compensated by reducing the installed distances, and functioning gear set is still obtained. Different addendum and dedendum factors are used for different vehicle gear systems. Figure 5.1 shows the extent to which these design strategies differ, using the 1 rear axle gear sets from Fig. 5.1 as examples. Fig. 5.1 Total contact ratio as function of the sum of pinion and wheel tooth numbers Fig. 5.1 Total contact ratio of sample gears as function of the sum of pinion and wheel tooth numbers5.2 Noise Excitation by Means of Gear Tooth Design 2 Spiral Angle The spiral angle is frequently used to alter the ratio between the axial and radial tooth forces. The spiral angle is als| Model Type | Helical gear box H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 11880.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 1230000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | FLENDER TÜBINGEN GMBH |

| Country of Manufacture | China |

| Data Sheet & Drawings | H4-CV-27-A multistage gear units up to the torque Nm are l Helical gear box H4 |