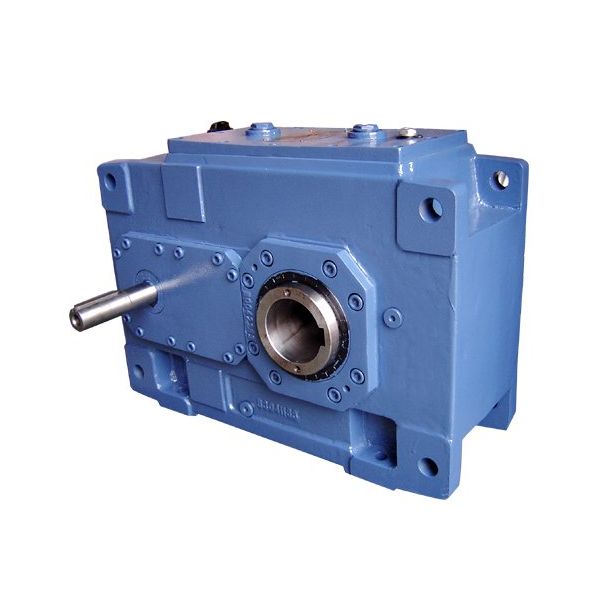

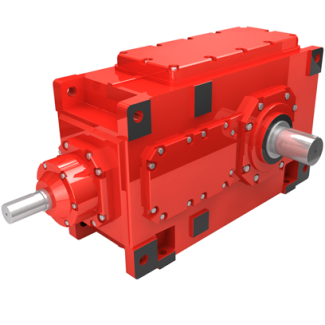

H4-CV-12-D haft LSS top H Gear unit size Helical gearbox H4

In stock

SKU

H4-CV-12-D

$13,392.86

Flender/Flender Gear Units/Helical gearbox H4

hat has not been earthed. Perform potential equalisation in accordance with the applicable regulations and directives. Threaded holes are provided on the gear unit to establish an earth connection. This work must be carried out by specialists in electrical engineering.

on the gear unit to establish an earth connection. This work must be carried out by specialists in electrical engineering.  In the case of gear units that are operated in combination with electrical machines that generate current or through which

In the case of gear units that are operated in combination with electrical machines that generate current or through which  current flows (.. motors and generators), take measures to ensure that no current can flow through the gear unit. Current

current flows (.. motors and generators), take measures to ensure that no current can flow through the gear unit. Current  flowing through the gear unit can result in irreparable damage to rolling-contact bearings and gears. Short circuits, voltage flashovers and deposits of conductive dust, for example, can all allow current to flow. Use insulators and earth the gear unit properly. When removing any guards, store their fixings in safe place. Removed guards must be re-fitted prior to starting. Observe the notices mounted on the gear unit, .. rating plate, direction of rotation ar- row symbol, etc. The notices must be kept free from paint or dirt. Replace missing plates. Bolts which have been damaged during assembly or disassembly work must be re- placed with new ones of the same strength class and type. DANGER Danger to life when the system is switched on Death or serious injury will occur. Always shut down the gear unit and any oil supply system (whether separate or attached to the gear unit) before you perform any work. Secure the drive aggregate against being operated accidentally as follows: Turn off the key-operated switch. Remove the fuses in the power supply. Attach an information notice to the start switch, clearly stating that work is being car- ried out on the gear unit. Ensure that the entire system is not under load to avoid danger during dismantling work. Safety instructions 2.5 Intended use in potentially explosive atmosphere 2 Edition 0/2 B5-0 en WARNING Potentially explosive atmosphere can be ignited potentially explosive atmosphere can be ignited if electrosta

flowing through the gear unit can result in irreparable damage to rolling-contact bearings and gears. Short circuits, voltage flashovers and deposits of conductive dust, for example, can all allow current to flow. Use insulators and earth the gear unit properly. When removing any guards, store their fixings in safe place. Removed guards must be re-fitted prior to starting. Observe the notices mounted on the gear unit, .. rating plate, direction of rotation ar- row symbol, etc. The notices must be kept free from paint or dirt. Replace missing plates. Bolts which have been damaged during assembly or disassembly work must be re- placed with new ones of the same strength class and type. DANGER Danger to life when the system is switched on Death or serious injury will occur. Always shut down the gear unit and any oil supply system (whether separate or attached to the gear unit) before you perform any work. Secure the drive aggregate against being operated accidentally as follows: Turn off the key-operated switch. Remove the fuses in the power supply. Attach an information notice to the start switch, clearly stating that work is being car- ried out on the gear unit. Ensure that the entire system is not under load to avoid danger during dismantling work. Safety instructions 2.5 Intended use in potentially explosive atmosphere 2 Edition 0/2 B5-0 en WARNING Potentially explosive atmosphere can be ignited potentially explosive atmosphere can be ignited if electrosta| Model Type | Helical gearbox H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 625.000000 |

| Ratio Range | 1 : 125…450 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 78000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | FLENOER-GRAFFENSTA |

| Country of Manufacture | South Korea |

| Data Sheet & Drawings | H4-CV-12-D haft LSS top H Gear unit size Helical gearbox H4 |