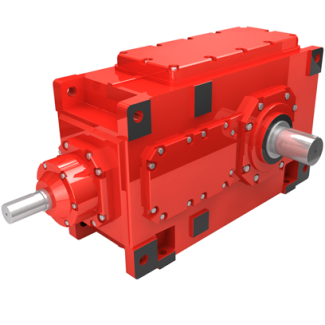

H4-CV-13-A Describe in the free text with hig h speed shaf Helical gear box H4

In stock

SKU

H4-CV-13-A

$18,750.00

Flender/Flender Gear Units/Helical gear box H4

hat is referred to as green our. Flour milled from freshly harvested wheat would require higher level of ADA. Higher levels would also be required for strong bakers and clears ours that are typicallyhigher in ash. Maximum allowable limit of

levels would also be required for strong bakers and clears ours that are typicallyhigher in ash. Maximum allowable limit of  ADA is 4 ppm in North America, and whenit is used as an oxidizing agent, such as bromate replacer, then

ADA is 4 ppm in North America, and whenit is used as an oxidizing agent, such as bromate replacer, then  the application rate ismuch higher than that used for maturing purposes. ADA is fast-acting and its action is fully completed

the application rate ismuch higher than that used for maturing purposes. ADA is fast-acting and its action is fully completed  at the end of the mixing stage in the baking process. In some processes involving longer fermentation, it may actually convert into biurea before the mixing stage, for it is highly reactive. One way to solvethat problem is by coating ADA and thus delaying its action. Coating, however, adds to the cost. There are two concentrations at which ADA is available in North America. The rst one is Maturox ( trade name) at 1% concentration premix and the second one isa premix of ADA concentrate at 2% concentration. The our mills in Canada routinely use this additive. 3.4.1.5.2 ascorbic acid. Similar to other additives, ascorbic acid is also sold as premix and is available under the trade names AA-1 and AA-2W. Ascorbic acid inthe past has been of only limited use, primarily owing to its cost. Since the removal ofpotassium bromate, it is quite commonly used by millers as an oxidizing agent. The typicalapplication rate is anywhere from 2 to 7 ppm. Its effect on increasing loaf volume maynot be as dramatic as would be expected from our treated with potassium bromate, but it provides tighter and ner grain in the bread crumb. It also helps extend the mix time in the baking process. The ascorbic acid requires enzymes in our to oxidize it to formdehydroascorbic acid. It is this dehydroascorbic acid that oxidizes the our. Therefore,the effect of ascorbic acid varies with our owing to the varying levels of enzymes present.Dehydroascorbic acid can not be used by itself, for it is highly unstable. As replacerfor potassium

at the end of the mixing stage in the baking process. In some processes involving longer fermentation, it may actually convert into biurea before the mixing stage, for it is highly reactive. One way to solvethat problem is by coating ADA and thus delaying its action. Coating, however, adds to the cost. There are two concentrations at which ADA is available in North America. The rst one is Maturox ( trade name) at 1% concentration premix and the second one isa premix of ADA concentrate at 2% concentration. The our mills in Canada routinely use this additive. 3.4.1.5.2 ascorbic acid. Similar to other additives, ascorbic acid is also sold as premix and is available under the trade names AA-1 and AA-2W. Ascorbic acid inthe past has been of only limited use, primarily owing to its cost. Since the removal ofpotassium bromate, it is quite commonly used by millers as an oxidizing agent. The typicalapplication rate is anywhere from 2 to 7 ppm. Its effect on increasing loaf volume maynot be as dramatic as would be expected from our treated with potassium bromate, but it provides tighter and ner grain in the bread crumb. It also helps extend the mix time in the baking process. The ascorbic acid requires enzymes in our to oxidize it to formdehydroascorbic acid. It is this dehydroascorbic acid that oxidizes the our. Therefore,the effect of ascorbic acid varies with our owing to the varying levels of enzymes present.Dehydroascorbic acid can not be used by itself, for it is highly unstable. As replacerfor potassium| Model Type | Helical gear box H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 875.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 90700 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | A. Friedr. Flender GmbH |

| Country of Manufacture | Spain |

| Data Sheet & Drawings | H4-CV-13-A Describe in the free text with hig h speed shaf Helical gear box H4 |