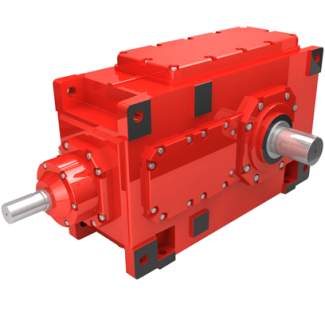

H4-CH-8B ings Our compact steel couplings provide extremely Helical gear units H4

In stock

SKU

H4-CH-8B

$7,821.43

Flender/Flender Gear Units/Helical gear units H4

glass melting tanks. If these and otier limit values to be expected in future are to be complied with,then this will only be possible with the current meltin tanks if downstream purification plants are used. These downstream flue DENOXplantsare concerned,arestilI

will only be possible with the current meltin tanks if downstream purification plants are used. These downstream flue DENOXplantsare concerned,arestilI  being tested. However, onethin isalreadycertain today: depending 9n the volume of the exhaust gas flows to be treated, anjgiven incorporation

being tested. However, onethin isalreadycertain today: depending 9n the volume of the exhaust gas flows to be treated, anjgiven incorporation  of DENOX plant, cost increase of DM 1 to 1 5 ertonne of glass is to be expected. At the

of DENOX plant, cost increase of DM 1 to 1 5 ertonne of glass is to be expected. At the  current, relatively low price of energy,thecostsof mekng energyareabout DM 3 pertonneof glass.* further reduction of the specific energy consumption - which is alreadyvery difficult toachieve, as the current tanks have reached their limits - would thus signify potential saving consider- ably below the potential saving of low-cost method for treating exhaust gases. These consi- derations were the starting point for development of completely new type of melting tank, with the goal not only of meeting the demands of the Technical Directive on Air Pollution, but also of exceeding them without downstream secondary equipment.The greatest emphasis in the context of this new design was to be placed on as reat reduction of the NOx value as ossible, as it must be assumed that the NO, value in exzaust gas will, sometime in the future, ge reduced to the general limit value 5 mg/Nm3 stipulated in the Technical Directive on Air Pollution. Low nitrogen oxide values can be achieved through number of primary measures.These in- clude reduction of the combustion air temperature, almost stoichiometric combustion or, if . possible, even sub-stoichiometric combustion with step-by-step postcombustion, as well as ow melting chamber temperature. The first of these demands - low combustion air temperatures - cannot be met economically with regenerative tank. The result would be considerably higher specificenergy consump- tionand,thus,an increaseintheexhaust gasmassflow. Inv

current, relatively low price of energy,thecostsof mekng energyareabout DM 3 pertonneof glass.* further reduction of the specific energy consumption - which is alreadyvery difficult toachieve, as the current tanks have reached their limits - would thus signify potential saving consider- ably below the potential saving of low-cost method for treating exhaust gases. These consi- derations were the starting point for development of completely new type of melting tank, with the goal not only of meeting the demands of the Technical Directive on Air Pollution, but also of exceeding them without downstream secondary equipment.The greatest emphasis in the context of this new design was to be placed on as reat reduction of the NOx value as ossible, as it must be assumed that the NO, value in exzaust gas will, sometime in the future, ge reduced to the general limit value 5 mg/Nm3 stipulated in the Technical Directive on Air Pollution. Low nitrogen oxide values can be achieved through number of primary measures.These in- clude reduction of the combustion air temperature, almost stoichiometric combustion or, if . possible, even sub-stoichiometric combustion with step-by-step postcombustion, as well as ow melting chamber temperature. The first of these demands - low combustion air temperatures - cannot be met economically with regenerative tank. The result would be considerably higher specificenergy consump- tionand,thus,an increaseintheexhaust gasmassflow. Inv| Model Type | Helical gear units H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 365.000000 |

| Ratio Range | 1 : 125…450 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 27200 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Limited. |

| Country of Manufacture | China |

| Data Sheet & Drawings | H4-CH-8B ings Our compact steel couplings provide extremely Helical gear units H4 |