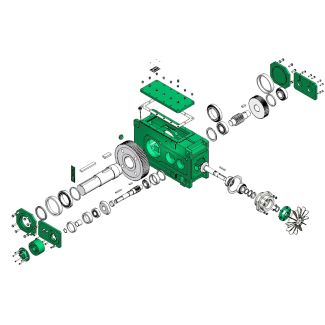

H4-CH-22B g Services Support and Consulting Services Spar Helical gear units H4

In stock

SKU

H4-CH-22B

$173,571.43

Flender/Flender Gear Units/Helical gear units H4

h changes (Fig. . 4 DeEll et al. Fig. 3 The inuence of extreme 2and CO 2concentrations on CO 2production of mungbean sprouts stored at 8 . (Adapted from Ref. 1.) Changes in respiration are often related to developmental changes

of mungbean sprouts stored at 8 . (Adapted from Ref. 1.) Changes in respiration are often related to developmental changes  within the prod- uct. However, specic metabolic changes may occur without measurable changes in netrespiration (. Whenever respiration and ATP

within the prod- uct. However, specic metabolic changes may occur without measurable changes in netrespiration (. Whenever respiration and ATP  production increase, an increase in energyrequirements is expected. In such cases the storage of products at xed low 2concentra- tions

production increase, an increase in energyrequirements is expected. In such cases the storage of products at xed low 2concentra- tions  might cause problems, because energy needs are no longer met in these conditions. CA technology capable of responding to metabolic changes would be the alternative. Such dynamic control of storage conditions (5, focuses on the 2concentration when CO 2production is minimal (ACP; anaerobic compensation point). This, however, might not be the best procedure, since ACP tends to shift during storage, as observed in apple( and pear (Peppelenbos HW, unpublished data). An approach that focuses on thedetection of fermentation metabolites, such as ethanol, in the storage atmosphere has also been suggested (. 2.5.2 Temperature Control Strict temperature control in the distribution chain is prerequisite for optimal use of MA packages in practice, but in most countries the cool-chain between production, distribution, Postharvest Physiology of Fresh Produce 4 retail, and the consumer has many uncontrolled links. Changes in the permeabilities of most packaging lms to gases in response to changes in temperature are generally lessthan changes in product respiration. Most of todays existing plastic lms do not havethe proper 2/CO 2permeability ratio to provide the ideal MA for many commodities at given temperature. In view of all these variables and knowing that any change within or around the package will alter the dynamic equilibrium between the product and its environment, it is clear that knowledge about the limits of tolerance of certain commodityis even more import

might cause problems, because energy needs are no longer met in these conditions. CA technology capable of responding to metabolic changes would be the alternative. Such dynamic control of storage conditions (5, focuses on the 2concentration when CO 2production is minimal (ACP; anaerobic compensation point). This, however, might not be the best procedure, since ACP tends to shift during storage, as observed in apple( and pear (Peppelenbos HW, unpublished data). An approach that focuses on thedetection of fermentation metabolites, such as ethanol, in the storage atmosphere has also been suggested (. 2.5.2 Temperature Control Strict temperature control in the distribution chain is prerequisite for optimal use of MA packages in practice, but in most countries the cool-chain between production, distribution, Postharvest Physiology of Fresh Produce 4 retail, and the consumer has many uncontrolled links. Changes in the permeabilities of most packaging lms to gases in response to changes in temperature are generally lessthan changes in product respiration. Most of todays existing plastic lms do not havethe proper 2/CO 2permeability ratio to provide the ideal MA for many commodities at given temperature. In view of all these variables and knowing that any change within or around the package will alter the dynamic equilibrium between the product and its environment, it is clear that knowledge about the limits of tolerance of certain commodityis even more import| Model Type | Helical gear units H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 8100.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 470000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. Friedr. Flender AG & Co. KG |

| Country of Manufacture | Lithuania |

| Data Sheet & Drawings | H4-CH-22B g Services Support and Consulting Services Spar Helical gear units H4 |