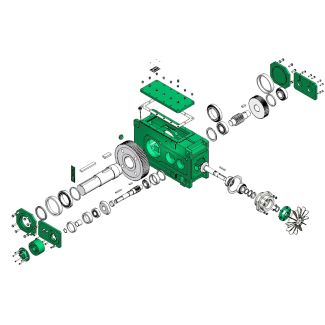

H4-CH-22-D tenance ServicesRetrofit and Modernization Ser Helical gear boxes H4

In stock

SKU

H4-CH-22-D

$173,571.43

Flender/Flender Gear Units/Helical gear boxes H4

h extends from raw material dosing and balling to process gas cleaning, and also includes coal-gasification plant for energy generation is less than two hectares (five acres). The CPT indura- tion furnace will be fired using com- bination of coal

is less than two hectares (five acres). The CPT indura- tion furnace will be fired using com- bination of coal  gas and heavy fuel oil. Plant start-up is scheduled for the second half of 2 and the produced pellets will

gas and heavy fuel oil. Plant start-up is scheduled for the second half of 2 and the produced pellets will  be mainly used by the Indian iron and steel industry. Features and benefits of CPT plants CPT represents the worlds

be mainly used by the Indian iron and steel industry. Features and benefits of CPT plants CPT represents the worlds  most com- pact plant for pelletizing and sets new benchmarks for cost-efficient iron and steel production on the basis of iron ore pellets. Plant modules are available for pellet-production outputs ranging from 8,0 / to 3 million /. Thanks to the circular design of the induration furnace, space requirements for com-plete CPT facility are less than 5 per -cent of those needed for convention-al pelletizing plant of similar capacity. Capital expenditures for civil works, equipment and steel structures are reduced accordingly. Faster plant com-pletions and start-ups allow producers to quickly commence with profitable pellet production. The circular induration furnace results in far more efficient utilization of installed equipment because more than 7 percent of the pallet cars are in use within the induration furnace. This is in contrast to conventional pelletiz-ing plant where less than 4 percent of the pallet cars are actually involved in producing pellets. (This is due to the lin-ear layout of straight-type induration furnace, which means that the pallet car strand returns empty to the green- pellet charging area.) The optimized utilization of recovered hot process gases in CPT minimizes the energy consumption required for pelletizing. Total recycling loops for waste materi-als and steel-mill reverts lead to low environmental impact. Plant operation is based on the use of well-proven Siemens auto mation systems for equip- ment and process control. CPT thus represents n

most com- pact plant for pelletizing and sets new benchmarks for cost-efficient iron and steel production on the basis of iron ore pellets. Plant modules are available for pellet-production outputs ranging from 8,0 / to 3 million /. Thanks to the circular design of the induration furnace, space requirements for com-plete CPT facility are less than 5 per -cent of those needed for convention-al pelletizing plant of similar capacity. Capital expenditures for civil works, equipment and steel structures are reduced accordingly. Faster plant com-pletions and start-ups allow producers to quickly commence with profitable pellet production. The circular induration furnace results in far more efficient utilization of installed equipment because more than 7 percent of the pallet cars are in use within the induration furnace. This is in contrast to conventional pelletiz-ing plant where less than 4 percent of the pallet cars are actually involved in producing pellets. (This is due to the lin-ear layout of straight-type induration furnace, which means that the pallet car strand returns empty to the green- pellet charging area.) The optimized utilization of recovered hot process gases in CPT minimizes the energy consumption required for pelletizing. Total recycling loops for waste materi-als and steel-mill reverts lead to low environmental impact. Plant operation is based on the use of well-proven Siemens auto mation systems for equip- ment and process control. CPT thus represents n| Model Type | Helical gear boxes H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 8100.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 470000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | FLENDER ZAHNRADGETRIEBE |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | H4-CH-22-D tenance ServicesRetrofit and Modernization Ser Helical gear boxes H4 |