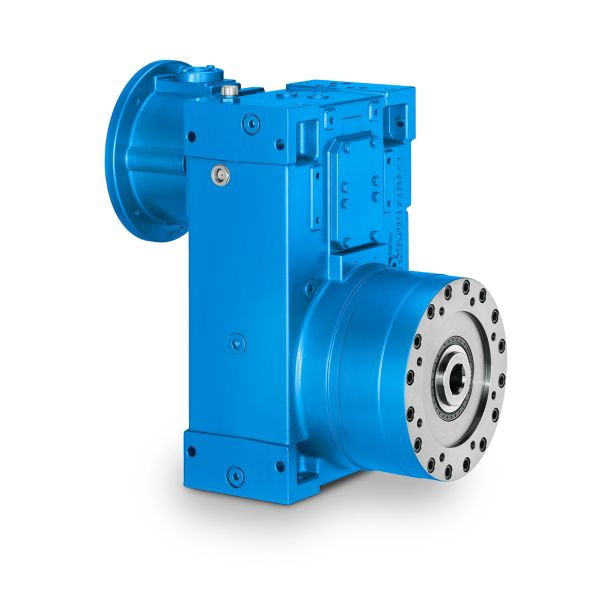

Flender/Flender Gear Units/Helical speed reducers H3

cost savings for each ECM: The 2 aeration energy consumption and cost of 4,7,8kWh/yr and R2.9 million was used as the baseline. Electricity rates given in ESKOMs Megaflex 1 kV tariff in Section 4.5.2 An emission factor of 0.9 kgCO

the baseline. Electricity rates given in ESKOMs Megaflex 1 kV tariff in Section 4.5.2 An emission factor of 0.9 kgCO  2e/kWh of electricity was applied to estimate carbon reduction. Equipment cost estimates were obtained from local suppliers. Engineering and construction

2e/kWh of electricity was applied to estimate carbon reduction. Equipment cost estimates were obtained from local suppliers. Engineering and construction  costs were estimated based on the Module 2 construction costs 4.7.1 Simple Measures Optimised Process and Aeration Control This measure

costs were estimated based on the Module 2 construction costs 4.7.1 Simple Measures Optimised Process and Aeration Control This measure  involves adjusting the process operating and aeration control parameters to model predicted optimal values as detailed in Section 4.6. 1. The model predicted opti mal operating parameters based on the 2 flow, load and wastewater characteristics data are: Winter (June-September) sludge age approximately 2-3 days Summer (October-May) sludge age approximately 1-2 days -recycle to be drawn from last aerobic cell and increased to an average of 4xADWF in order to meet the nitrate/nitrite final effluent limit. Depending on the final effluent nitrate/nitrite concentration, the -recycle should be varied from minimum of 2xADWF at lowest winter temperature of 1 oC to maximum of 6xADWF at summe mixed liquid temperatures above 2oC. Blower and airflow control to be adjusted using the existing algorithm to maintain on average DO setpoints in Cells 1, 1, 1 and 1 at 1, 1,0.5 0.5 mg/ respectively. The model predicted aeration energy consumption and cost savings as well as final effluent quality are given in Table 4-1. Also included are the 2 baseline values for comparison. Table 4-1: Zeekoegat WWTP Model Predicted Paramete rs for Implementing Optimised Process Control Units Baseline ( Optimised Process Control Aeration Energy Parameter Consumption MWh/yr 4,6 4,2 Consumption Saving MWh/yr 4 % Consumption Saving % 9 Consumption Cost /yr 2,9,1 2,6,1 Consumption Cost Saving /yr 2,9 % Consumption Cost Saving % 1 D

involves adjusting the process operating and aeration control parameters to model predicted optimal values as detailed in Section 4.6. 1. The model predicted opti mal operating parameters based on the 2 flow, load and wastewater characteristics data are: Winter (June-September) sludge age approximately 2-3 days Summer (October-May) sludge age approximately 1-2 days -recycle to be drawn from last aerobic cell and increased to an average of 4xADWF in order to meet the nitrate/nitrite final effluent limit. Depending on the final effluent nitrate/nitrite concentration, the -recycle should be varied from minimum of 2xADWF at lowest winter temperature of 1 oC to maximum of 6xADWF at summe mixed liquid temperatures above 2oC. Blower and airflow control to be adjusted using the existing algorithm to maintain on average DO setpoints in Cells 1, 1, 1 and 1 at 1, 1,0.5 0.5 mg/ respectively. The model predicted aeration energy consumption and cost savings as well as final effluent quality are given in Table 4-1. Also included are the 2 baseline values for comparison. Table 4-1: Zeekoegat WWTP Model Predicted Paramete rs for Implementing Optimised Process Control Units Baseline ( Optimised Process Control Aeration Energy Parameter Consumption MWh/yr 4,6 4,2 Consumption Saving MWh/yr 4 % Consumption Saving % 9 Consumption Cost /yr 2,9,1 2,6,1 Consumption Cost Saving /yr 2,9 % Consumption Cost Saving % 1 D| Model Type | Helical speed reducers H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 875.000000 |

| Ratio Range | 1 : 25…90 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 35700 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | N.V. Flender Belge S.A. |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | H3-VV9-B eupex Helical speed reducers H3 |