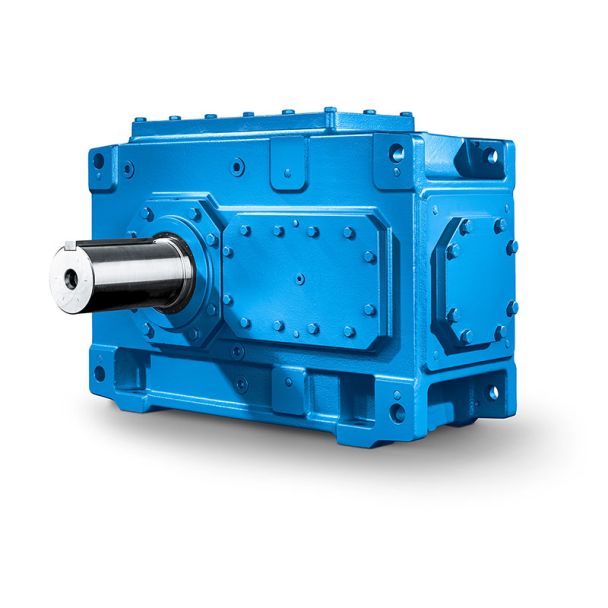

H3-VV-7-D gearbox flender catalogue Helical speed reduction gearbox H3

In stock

SKU

H3-VV-7-D

$11,571.43

Flender/Flender Gear Units/Helical speed reduction gearbox H3

cooling and/or noncontacting shaft seals should be filled with preservative agent and run without load. 7.3.1.3 Interiorpreservation procedure Stop the gear unit. Drain oil into suitable container (see section 1, "Maintenance and Repair"). Unscrew the air filter including the reducing

gear unit. Drain oil into suitable container (see section 1, "Maintenance and Repair"). Unscrew the air filter including the reducing  screw. Pour in the preservative agent through the hole of the reducing screw up to the top mark on the

screw. Pour in the preservative agent through the hole of the reducing screw up to the top mark on the  oilsight glass. For preservative agent see table 1 or 1 in item 4.4.1! Screw in the air filter including reducing

oilsight glass. For preservative agent see table 1 or 1 in item 4.4.1! Screw in the air filter including reducing  screw. Start the gear unit and allow it to idle briefly. Unscrew the oildrain plug. Drain preservative agent into suitable container. Dispose of preservative agent in accordance with regulations. There is risk of scalding from the hot preservative agent draining from the gear unit. Wear protective gloves! Screw in the oildrain plug. Replace air filter with screw plug. Before restarting the gear unit, replace the screw plug with the air filter. Observe the instructions in item 7.1.1. 7.3.2 Exterior preservation 7.3.2.1 Exteriorpreservation procedure Clean the surfaces. For separation between the sealing lip of the shaftsealing ring and the preservative agent, the shaft should be brushed with grease in way of the sealing lip. Apply preservative agent. For preservative agent see table 1 in item 4.4.2! 9 / 1BA 5 en 0/2.4 Greaselubricated rolling bearing The gear unit is delivered ex works with the necessary grease charge for the lower outputshaft bearing. Fig. 7: Lubricating point for lower outputshaft bearing of type .BV Fig. 7: Lubricating point for lower outputshaft bearing of type B3BV 5 Lubricating point 6 Greaselubricated rolling bearing detailed view of the gear unit can be obtained from the drawings in the gearunit documentation. If the gear unit has not been in use for more than 3 months or if the lower outputshaft bearing has been inspected or renewed, the bearing space must be filled with the amount of rollingbearing grease specified in Table 3.

screw. Start the gear unit and allow it to idle briefly. Unscrew the oildrain plug. Drain preservative agent into suitable container. Dispose of preservative agent in accordance with regulations. There is risk of scalding from the hot preservative agent draining from the gear unit. Wear protective gloves! Screw in the oildrain plug. Replace air filter with screw plug. Before restarting the gear unit, replace the screw plug with the air filter. Observe the instructions in item 7.1.1. 7.3.2 Exterior preservation 7.3.2.1 Exteriorpreservation procedure Clean the surfaces. For separation between the sealing lip of the shaftsealing ring and the preservative agent, the shaft should be brushed with grease in way of the sealing lip. Apply preservative agent. For preservative agent see table 1 in item 4.4.2! 9 / 1BA 5 en 0/2.4 Greaselubricated rolling bearing The gear unit is delivered ex works with the necessary grease charge for the lower outputshaft bearing. Fig. 7: Lubricating point for lower outputshaft bearing of type .BV Fig. 7: Lubricating point for lower outputshaft bearing of type B3BV 5 Lubricating point 6 Greaselubricated rolling bearing detailed view of the gear unit can be obtained from the drawings in the gearunit documentation. If the gear unit has not been in use for more than 3 months or if the lower outputshaft bearing has been inspected or renewed, the bearing space must be filled with the amount of rollingbearing grease specified in Table 3.| Model Type | Helical speed reduction gearbox H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 540.000000 |

| Ratio Range | 1 : 25…90 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 21700 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Siemens AG |

| Country of Manufacture | Papua New Guinea |

| Data Sheet & Drawings | H3-VV-7-D gearbox flender catalogue Helical speed reduction gearbox H3 |