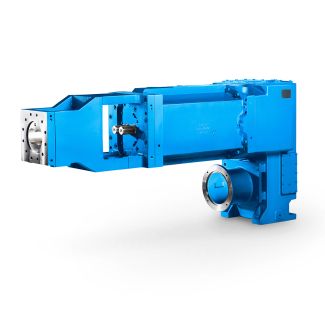

H3-VH22A flender himmel motors Helical gearboxes H3

In stock

SKU

H3-VH22A

$210,000.00

Flender/Flender Gear Units/Helical gearboxes H3

concerns components that must be dismantled when mounting the drive or for some other purpose. For multi- layer color structures, the risk of damage due to slings or tools is considerably higher than for the design with plastic powder. The

the risk of damage due to slings or tools is considerably higher than for the design with plastic powder. The  gears are delivered preserved. Standard packaging The packaging on wooden frames is included in the standard delivery kit (as far

gears are delivered preserved. Standard packaging The packaging on wooden frames is included in the standard delivery kit (as far  as possible). Upon request, the packaging can also be shrink-wrapped. Optionally, deliveries can also be delivered in containers or in

as possible). Upon request, the packaging can also be shrink-wrapped. Optionally, deliveries can also be delivered in containers or in  stackable wooden crates for container transport. Please contact Flender to find out about the additional efforts. Flender GmbH 2NER GROUP CO.,LIMITED Germany sogears HB series gearbox 2/6 Flender MD 2.1 2Introduction Notes Information about basics Overview (continued) Interior preservation of gear units Without additional measures, the corrosion protection for stan- dard packaged gear units will last up to 6 months when trans- ported and stored in dry, draft-free and closed room without major temperature fluctuations. The service life differs depending on the type of packaging. Overview of the basic service life (in months) of the gear unit' interior preservation for hermetically sealed gear units: When labyrinth seals with -ring are used, the service life is halved (upper limit value 1 months). The internal preservation of Flender gear units is dependent on the oil used and the shaft seals provided. If the storage periods mentioned are exceeded, the anti corro- sive agent in the gear unit must be renewed. If gear units are stored outdoors, the maximum permissible storage time might be as little as 1 months depending on the packaging used. Observe operating instructions!Lubrication of Flender gear units Dip lubrication There are 2 types of dip lubrication. 1. Rotating components (toothed gears, roller bearings) are im- mersed in oil to the extent prescribed. Due to rotation at high circumferential speed, all of the points of these components are immersed in oil dur

stackable wooden crates for container transport. Please contact Flender to find out about the additional efforts. Flender GmbH 2NER GROUP CO.,LIMITED Germany sogears HB series gearbox 2/6 Flender MD 2.1 2Introduction Notes Information about basics Overview (continued) Interior preservation of gear units Without additional measures, the corrosion protection for stan- dard packaged gear units will last up to 6 months when trans- ported and stored in dry, draft-free and closed room without major temperature fluctuations. The service life differs depending on the type of packaging. Overview of the basic service life (in months) of the gear unit' interior preservation for hermetically sealed gear units: When labyrinth seals with -ring are used, the service life is halved (upper limit value 1 months). The internal preservation of Flender gear units is dependent on the oil used and the shaft seals provided. If the storage periods mentioned are exceeded, the anti corro- sive agent in the gear unit must be renewed. If gear units are stored outdoors, the maximum permissible storage time might be as little as 1 months depending on the packaging used. Observe operating instructions!Lubrication of Flender gear units Dip lubrication There are 2 types of dip lubrication. 1. Rotating components (toothed gears, roller bearings) are im- mersed in oil to the extent prescribed. Due to rotation at high circumferential speed, all of the points of these components are immersed in oil dur| Model Type | Helical gearboxes H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 9800.000000 |

| Ratio Range | 1 : 25…100 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 470000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Oy |

| Country of Manufacture | Japan |

| Data Sheet & Drawings | H3-VH22A flender himmel motors Helical gearboxes H3 |