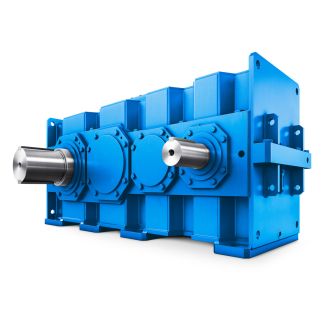

H3-FH-11-A gear motor flender Helical gear unit H3

In stock

SKU

H3-FH-11-A

$30,000.00

Flender/Flender Gear Units/Helical gear unit H3

er expert guidance and supervision. And wide range of products and ac - cessories can be found right next door!Robotic welding cellsWhen it comes to the automation of welding operations we are able to develop complete solutions for all conventional

welding cellsWhen it comes to the automation of welding operations we are able to develop complete solutions for all conventional  technolo - gies (.. spot welding, MIG/MAG, TIG) and for laser welding. Our vendor-neutral robotic welding cells are constructed on

technolo - gies (.. spot welding, MIG/MAG, TIG) and for laser welding. Our vendor-neutral robotic welding cells are constructed on  modular principles. This approach really pays off, as the robust and com - pact units can be easily transported and

modular principles. This approach really pays off, as the robust and com - pact units can be easily transported and  put into operation thanks to plug play technology. Sustaining value It is part of our philosophy to ensure that we do not lose track of your welding equipment even after the sale has been made. Our skilled technicians are on hand to carry out regular maintenance, calibration and validation work and are also available to under - take periodic safety testing. And if for some reason things stop running smoothly we can come out as soon as you need us. We are able to repair welding equipment of any kind, whatever the manufacturer. Thanks to our massive spare parts warehouse repair can usually be effected immediately. This keeps downtime to minimum and provides valuable flexibility. INCLUDING SPECIAL ORDERS!WELDING TECHNOLOGY QUALITY YOU CAN DEPEND ON! Often it is the small things that matter most when it comes to the smooth running of large machine. With Blumenbecker you get the full range of rotary and linear drive technology. And every- thing built to quality that you can rely on completely. The machine runs and runs and runs.... This is what we like to hear, as it confirms our philosophy that special attention should always be paid to the machine drive system. For us this attention begins with comprehensive technical and commercial consultation. For the last 5 or so years we have been partners with market leaders SKF and can also supply products from well-known manufacturers such as Siemens/Flender, OKS, Loctite, Cooper, BoschRexrodt and OPTIBELT. Becaus

put into operation thanks to plug play technology. Sustaining value It is part of our philosophy to ensure that we do not lose track of your welding equipment even after the sale has been made. Our skilled technicians are on hand to carry out regular maintenance, calibration and validation work and are also available to under - take periodic safety testing. And if for some reason things stop running smoothly we can come out as soon as you need us. We are able to repair welding equipment of any kind, whatever the manufacturer. Thanks to our massive spare parts warehouse repair can usually be effected immediately. This keeps downtime to minimum and provides valuable flexibility. INCLUDING SPECIAL ORDERS!WELDING TECHNOLOGY QUALITY YOU CAN DEPEND ON! Often it is the small things that matter most when it comes to the smooth running of large machine. With Blumenbecker you get the full range of rotary and linear drive technology. And every- thing built to quality that you can rely on completely. The machine runs and runs and runs.... This is what we like to hear, as it confirms our philosophy that special attention should always be paid to the machine drive system. For us this attention begins with comprehensive technical and commercial consultation. For the last 5 or so years we have been partners with market leaders SKF and can also supply products from well-known manufacturers such as Siemens/Flender, OKS, Loctite, Cooper, BoschRexrodt and OPTIBELT. Becaus| Model Type | Helical gear unit H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 1400.000000 |

| Ratio Range | 1 : 25…90 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 61600 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | FLENDER GUSS GMBH |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | H3-FH-11-A gear motor flender Helical gear unit H3 |