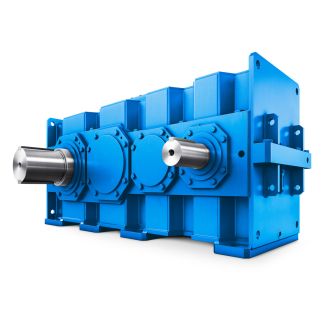

H3-FH-11-D flender himmel germany Helical gear reducer H3

In stock

SKU

H3-FH-11-D

$30,000.00

Flender/Flender Gear Units/Helical gear reducer H3

er head allows the production of bevel gears in so-called two-ank cut process, meaning that the two anks of bevel gear are manufacturedin single operation. further advantage is that lengthwise crowning can be simplyproduced and can be adjusted continuously without

gear are manufacturedin single operation. further advantage is that lengthwise crowning can be simplyproduced and can be adjusted continuously without  tilting the cutter (see Sect.3.2.1 ). The cutter blades are standardized and each size is employed for specic range of

tilting the cutter (see Sect.3.2.1 ). The cutter blades are standardized and each size is employed for specic range of  modules. The Zyklo-Palloid method is used for both soft and hard cutting.Hard cutting processes are designated as HPG- for small

modules. The Zyklo-Palloid method is used for both soft and hard cutting.Hard cutting processes are designated as HPG- for small  modules ( /C2 mm) and HPG for larger modules. For spiral bevel gears with diameters above 1,2 mm, the Zyklo-Palloid method is currently the only process which allows hard nishing (see Sect. 6.. Soft cutting is always performed using an oil based cooling lubricant, whereas hard nishing is dry cutting operation. Palloid This process differs fundamentally from all other processes since the tool employed is tapered hob similar to Christmas tree (see Fig. 6. rather than face cutter head. The method is used to generate spiral bevel gears of constant toothdepth in conventional hobbing process which produces an involute tooth trace. Inthe normal section, the tooth thickness, space width and slot width are constant alongthe face width. This tooth form results in very light sensitivity of the contact pattern tothe relative displacements of the mating gears (see Sect. 3.4.4 ), giving Palloid gears special merits over other spiral bevel gear types. Lengthwise crowning and some prole modications are achieved by regrinding the tool. Additional ank modica- tions are made by means of the manufacturing kinematics. One disadvantage of thisprocess lies in the special tool which needs to be adapted for different types of ank2.1 Classication of Bevel Gears 1 modication. For example, change in tooth thickness requires different tool. The largest available cutter module is currently limited to 8 mm. further disadvantage isits lower productivity when compared to modern

modules ( /C2 mm) and HPG for larger modules. For spiral bevel gears with diameters above 1,2 mm, the Zyklo-Palloid method is currently the only process which allows hard nishing (see Sect. 6.. Soft cutting is always performed using an oil based cooling lubricant, whereas hard nishing is dry cutting operation. Palloid This process differs fundamentally from all other processes since the tool employed is tapered hob similar to Christmas tree (see Fig. 6. rather than face cutter head. The method is used to generate spiral bevel gears of constant toothdepth in conventional hobbing process which produces an involute tooth trace. Inthe normal section, the tooth thickness, space width and slot width are constant alongthe face width. This tooth form results in very light sensitivity of the contact pattern tothe relative displacements of the mating gears (see Sect. 3.4.4 ), giving Palloid gears special merits over other spiral bevel gear types. Lengthwise crowning and some prole modications are achieved by regrinding the tool. Additional ank modica- tions are made by means of the manufacturing kinematics. One disadvantage of thisprocess lies in the special tool which needs to be adapted for different types of ank2.1 Classication of Bevel Gears 1 modication. For example, change in tooth thickness requires different tool. The largest available cutter module is currently limited to 8 mm. further disadvantage isits lower productivity when compared to modern| Model Type | Helical gear reducer H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 1400.000000 |

| Ratio Range | 1 : 25…90 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 61600 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | N.V. Flender Belge S.A. |

| Country of Manufacture | China |

| Data Sheet & Drawings | H3-FH-11-D flender himmel germany Helical gear reducer H3 |