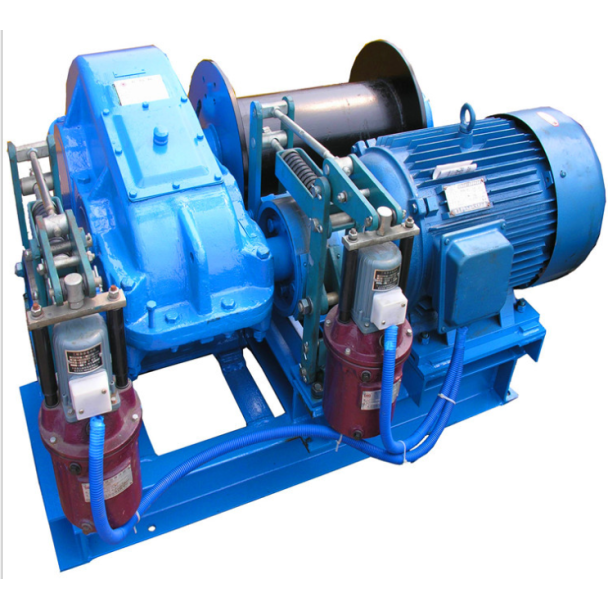

H3-DV14A flender ersatzteile Helical speed reducer H3

In stock

SKU

H3-DV14A

$56,250.00

Flender/Flender Gear Units/Helical speed reducer H3

ect on our doughs. The color progressively darkens with time. This meansfurther deterioration of the color and color stability of the dough and resultant products as the our is processed in the secondary-processing industries. Additionally, freshly milled ours generally have

the dough and resultant products as the our is processed in the secondary-processing industries. Additionally, freshly milled ours generally have  creamy color. From the foregoing, it is obvious that much of the our appearance problem (color and dress) can be

creamy color. From the foregoing, it is obvious that much of the our appearance problem (color and dress) can be  resolved through appropriate our dressing in the sifters and by control-ling the our extraction rate to point where the problems

resolved through appropriate our dressing in the sifters and by control-ling the our extraction rate to point where the problems  related to the bran specks,color of the our, color stability of the dough, and subsequently its processed products, Table 1 Minimum Levels of Nutrient Requirement ofFlour in Canada Minimum Nutrient (mg/1 ) Thiamin 0.6 Riboavin 0.4 Niacin 5.3 Iron 4.4 Folic acid 0.1 aSource : FDA requirements. 3 Sarkar cease to exist. Flour color whether dark (high extraction) or creamy/yellowish (freshly milled) has good correlation with nished product color. Therefore, to obtain whitercrumb in bread the our also has to become whiter. The creamy color of the freshly milledour is due to the presence of carotenoid pigments. There are two ways to reduce oreliminate this: () natural aging of our, () whitening of our through additives. 3.4.1.2.1 natural aging. few weeks of storage following the production of our tends to whiten the our by reducing the pigmentation. This is referred to as natural aging of our. In addition to the improvement in our color, the aging process also has benecial effects on the dough characteristics and the nished product quality. There area number of countries where our is not allowed to be treated chemically. In such situa-tions our is kept in the storage bins for about 1 week to almost 4 weeks before bagging and shipping. During this time the our may be homogenized by turning it over. It is obviously an expensive proposition to carry the our for number of weeks after itsproduction. Economical solutions are available in which our is allowed to b

related to the bran specks,color of the our, color stability of the dough, and subsequently its processed products, Table 1 Minimum Levels of Nutrient Requirement ofFlour in Canada Minimum Nutrient (mg/1 ) Thiamin 0.6 Riboavin 0.4 Niacin 5.3 Iron 4.4 Folic acid 0.1 aSource : FDA requirements. 3 Sarkar cease to exist. Flour color whether dark (high extraction) or creamy/yellowish (freshly milled) has good correlation with nished product color. Therefore, to obtain whitercrumb in bread the our also has to become whiter. The creamy color of the freshly milledour is due to the presence of carotenoid pigments. There are two ways to reduce oreliminate this: () natural aging of our, () whitening of our through additives. 3.4.1.2.1 natural aging. few weeks of storage following the production of our tends to whiten the our by reducing the pigmentation. This is referred to as natural aging of our. In addition to the improvement in our color, the aging process also has benecial effects on the dough characteristics and the nished product quality. There area number of countries where our is not allowed to be treated chemically. In such situa-tions our is kept in the storage bins for about 1 week to almost 4 weeks before bagging and shipping. During this time the our may be homogenized by turning it over. It is obviously an expensive proposition to carry the our for number of weeks after itsproduction. Economical solutions are available in which our is allowed to b| Model Type | Helical speed reducer H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 2625.000000 |

| Ratio Range | 1 : 28…112 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 113000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | FLENDER GUSS GMBH |

| Country of Manufacture | China |

| Data Sheet & Drawings | H3-DV14A flender ersatzteile Helical speed reducer H3 |