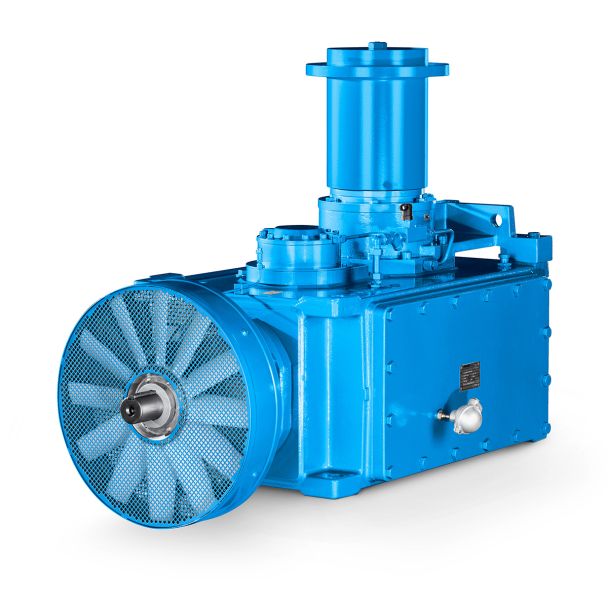

Helical speed reducer H3 flender hrvatska H3-CV-5-A

In stock

SKU

H3-CV-5-A

$6,857.14

Flender/Flender Gear Units/Helical speed reducer H3

ddition to construction work and road layout. The grinding plants designed capacity will be 1 tph of OPC at 3 cm2/ according to Blaine. Christian Pfeiffers scope of supply also includes 2-chamber ball mill with slide shoe bearing (4.8 dia.

cm2/ according to Blaine. Christian Pfeiffers scope of supply also includes 2-chamber ball mill with slide shoe bearing (4.8 dia.  1 ), featuring wear resistant shell liner made of progressive lifters for the first grinding chamber, the latest intermediate diaphragm

1 ), featuring wear resistant shell liner made of progressive lifters for the first grinding chamber, the latest intermediate diaphragm  of the 4 th generation with optimised centre, classifying lining in the second chamber, as well as QDK 2Z separator

of the 4 th generation with optimised centre, classifying lining in the second chamber, as well as QDK 2Z separator  with filter system. The delivery will also comprise 2 1 0 silos with total of 4 bulk loads for trucks, 2 big bag loading stations, as well as packing and palletising installation for truck loading with capacity of 3 bags/hour. One of the silos will include one-chamber system, while the second will be equipped with two-chamber system. The grinding plant will have specific energy demand of less than 4 kW/ of OPC. Construction work began in July 2, and the project is due for completion and commissioning in late summer 2. Indonesia Cement plant in Balikpapan orders Capstone microturbine Capstone Turbine Corporation has received an order for Capstone C8 system for cement plant in Balikpapan, Indonesia. The plant will be powered exclusively by the Capstone C8 microturbine, which will replace the facilitys existing diesel reciprocating generation equipment. The microturbine is standalone unit, enabling the cement plant to achieve independence from electric utilities. Serba Dinamik, Capstones distributor for Indonesia, Malaysia and Brunei, secured the order. Commissioning is scheduled for September 2. Consistent-quality cement without wasting watt. Imagine 3 percent reduction in the energy consumed by conveyors, crushers, mills, fans and pumps used throughout your cement plant. ABBs ACS 2 medium voltage variable speed drive could be the answer. For motor-driven applications, the general-purpose drive replaces traditional throttling or damping d

with filter system. The delivery will also comprise 2 1 0 silos with total of 4 bulk loads for trucks, 2 big bag loading stations, as well as packing and palletising installation for truck loading with capacity of 3 bags/hour. One of the silos will include one-chamber system, while the second will be equipped with two-chamber system. The grinding plant will have specific energy demand of less than 4 kW/ of OPC. Construction work began in July 2, and the project is due for completion and commissioning in late summer 2. Indonesia Cement plant in Balikpapan orders Capstone microturbine Capstone Turbine Corporation has received an order for Capstone C8 system for cement plant in Balikpapan, Indonesia. The plant will be powered exclusively by the Capstone C8 microturbine, which will replace the facilitys existing diesel reciprocating generation equipment. The microturbine is standalone unit, enabling the cement plant to achieve independence from electric utilities. Serba Dinamik, Capstones distributor for Indonesia, Malaysia and Brunei, secured the order. Commissioning is scheduled for September 2. Consistent-quality cement without wasting watt. Imagine 3 percent reduction in the energy consumed by conveyors, crushers, mills, fans and pumps used throughout your cement plant. ABBs ACS 2 medium voltage variable speed drive could be the answer. For motor-driven applications, the general-purpose drive replaces traditional throttling or damping d| Model Type | Helical speed reducer H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 320.000000 |

| Ratio Range | 1 : 25…90 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | – Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Siemens Industriegetriebe GmbH, Penig |

| Country of Manufacture | Saudi Arabia |

| Data Sheet & Drawings | Helical speed reducer H3 flender hrvatska H3-CV-5-A |