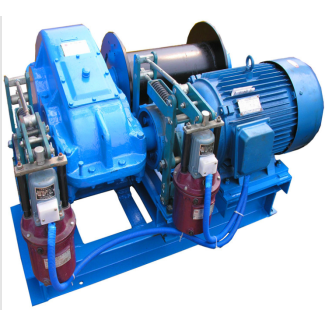

Flender/Flender Gear Units/Helical gear boxes H2

). Note that the total heat required to evaporate bound water is the sum of the latent heat of vaporization and the heat of wetting; the latter is function of the moisture content . The heat of wetting is 0

and the heat of wetting; the latter is function of the moisture content . The heat of wetting is 0  for unbound water and increases with decreasing . Since Hwis responsible for lowering the vapor pressure of bound water, at

for unbound water and increases with decreasing . Since Hwis responsible for lowering the vapor pressure of bound water, at  the same relative humidity, Hwis almost the same for all materials (Keey, . For most materials, the moisture-binding energy is

the same relative humidity, Hwis almost the same for all materials (Keey, . For most materials, the moisture-binding energy is  positive; generally it is mono- tonically decreasing function of the moisture content, with value of zero for unboundmoisture. For hydrophobic food materials (.., peanut oil or starches at lower tempera-tures) the binding energy can, however, be negative. In general, water sorption data must be determined experimentally. Some 8 correla- tions, ranging from those based on theory to those that are purely empirical, have appearedin the literature. Two of the most extensive compilations are developed by Wolf et al.( and Iglesias and Chirife (. Aside from temperature, the physical structure aswell as composition of the material also affect water sorption. The pore structure and sizeas well as physical or chemical transformations during drying can cause signicant varia- tions in the moisture-binding ability of the solid. 1.1.3 Water Activity In drying some materials that require careful hygiene attention (.., food), the availability of water for growth of microorganisms, germination of spores, and participation in severaltypes of chemical reaction becomes an important issue. This availability, which depends on relative pressure or water activity, , is dened as the ratio of the partial pressure, , of water over the wet solid system to the equilibrium vapor pressure pw, of water at the same temperature. Thus aw, which is also equal to the relative humidity of the surrounding humid air, is dened as: aw/H1p pw( Different Shapes of the Xversus awcurves are observed, depending on the type of material (.., high-, medi

positive; generally it is mono- tonically decreasing function of the moisture content, with value of zero for unboundmoisture. For hydrophobic food materials (.., peanut oil or starches at lower tempera-tures) the binding energy can, however, be negative. In general, water sorption data must be determined experimentally. Some 8 correla- tions, ranging from those based on theory to those that are purely empirical, have appearedin the literature. Two of the most extensive compilations are developed by Wolf et al.( and Iglesias and Chirife (. Aside from temperature, the physical structure aswell as composition of the material also affect water sorption. The pore structure and sizeas well as physical or chemical transformations during drying can cause signicant varia- tions in the moisture-binding ability of the solid. 1.1.3 Water Activity In drying some materials that require careful hygiene attention (.., food), the availability of water for growth of microorganisms, germination of spores, and participation in severaltypes of chemical reaction becomes an important issue. This availability, which depends on relative pressure or water activity, , is dened as the ratio of the partial pressure, , of water over the wet solid system to the equilibrium vapor pressure pw, of water at the same temperature. Thus aw, which is also equal to the relative humidity of the surrounding humid air, is dened as: aw/H1p pw( Different Shapes of the Xversus awcurves are observed, depending on the type of material (.., high-, medi| Model Type | Helical gear boxes H2 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 590.000000 |

| Ratio Range | 1 : 8…28 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 25600 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Power Transmission Inc. |

| Country of Manufacture | Colombia |

| Data Sheet & Drawings | H2-SH-8-D flender uae Helical gear boxes H2 |