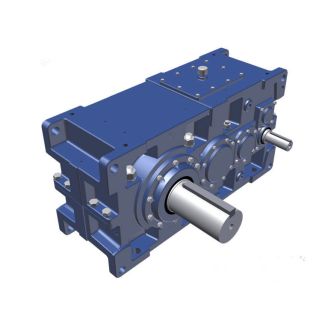

flender electric motor H2-DV25-B Helical gear reducer H2

In stock

SKU

H2-DV25-B

$334,285.71

Flender/Flender Gear Units/Helical gear reducer H2

and pitman 1. Inclined spring-loaded idler8. Roller chain drive 1. Quarter-turn -belt drive9. Main-drive shaft 1. PTO pulley (From Operators Manual of the Reaper. Issue 1; Aug 1.) Harvesting and Threshing 8 to the reaper input pulley through quarter-turn -belt

Manual of the Reaper. Issue 1; Aug 1.) Harvesting and Threshing 8 to the reaper input pulley through quarter-turn -belt  drive. springs loaded belt idler serves as tensioner and guides the -belt to track smoothly during operation. The inputpulley drives

drive. springs loaded belt idler serves as tensioner and guides the -belt to track smoothly during operation. The inputpulley drives  the cutter-bar assembly through the pitman rod and eccentric mechanism.The main shaft also drives the conveyor lugged belts by means

the cutter-bar assembly through the pitman rod and eccentric mechanism.The main shaft also drives the conveyor lugged belts by means  of sprockets and rollerchain. The lugs on the at-belt conveyor mesh with the star wheels and cause them to rotate. During the reaping operation, the gathering headers guide the crop to the star wheels that hold the crop while it is cut, then guide the crop into the double vertical at-beltconveyor. The pressure springs hold the crop against the conveyor until it is dischargedvertically into new windrow at the right side of the reaper for manual picking and tyingof crops with straw bunch. During operation, the vertically conveyed crops are laid onthe ground in clear windrow maintaining the direction of tillers perpendicular to the direction of travel, and none of the panicles come in contact with the moving parts of the machine. It is thus apparent that the operator always has to take left turn with the reaperduring harvesting. The CAAMSIRRI 1.0- reaper has pair of 4-mmdiameter, and 2-mm wide cage wheels, but it is not provided with differential and brake systems. This reaperperforms the cutting and windrowing operations very successfully during its lengthwise travel in high-density paddy and wheat elds. The only difculty faced with this type of reaper is that it is difcult to make proper turn and, therefore, reaping at the corners is never perfect. Research workers of various institutions, entrepreneurs, and private organi-zations have tested the reaper intensively and modied it accordingly to suit the localrequirements without altering the c

of sprockets and rollerchain. The lugs on the at-belt conveyor mesh with the star wheels and cause them to rotate. During the reaping operation, the gathering headers guide the crop to the star wheels that hold the crop while it is cut, then guide the crop into the double vertical at-beltconveyor. The pressure springs hold the crop against the conveyor until it is dischargedvertically into new windrow at the right side of the reaper for manual picking and tyingof crops with straw bunch. During operation, the vertically conveyed crops are laid onthe ground in clear windrow maintaining the direction of tillers perpendicular to the direction of travel, and none of the panicles come in contact with the moving parts of the machine. It is thus apparent that the operator always has to take left turn with the reaperduring harvesting. The CAAMSIRRI 1.0- reaper has pair of 4-mmdiameter, and 2-mm wide cage wheels, but it is not provided with differential and brake systems. This reaperperforms the cutting and windrowing operations very successfully during its lengthwise travel in high-density paddy and wheat elds. The only difculty faced with this type of reaper is that it is difcult to make proper turn and, therefore, reaping at the corners is never perfect. Research workers of various institutions, entrepreneurs, and private organi-zations have tested the reaper intensively and modied it accordingly to suit the localrequirements without altering the c| Model Type | Helical gear reducer H2 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 15600.000000 |

| Ratio Range | 1 : 6.3…20 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 860000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | N.V. Flender Belge S.A. |

| Country of Manufacture | Ecuador |

| Data Sheet & Drawings | flender electric motor H2-DV25-B Helical gear reducer H2 |