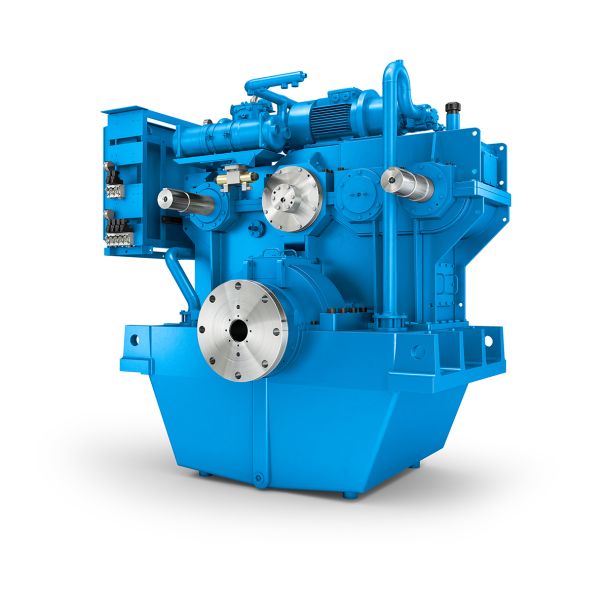

H1-SH-9B flendergetriebe Helical gear Reduction Boxes H1

In stock

SKU

H1-SH-9B

$18,492.86

Flender/Flender Gear Units/Helical gear Reduction Boxes H1

_________ TS NO.: MEC//2UU/0/2/0 Electrical system Chapter-0.0 2, MECON Limited, All Right Reserved Pag 2 of 2 1. Checking the functioning of various electrical schemes like aut change over, signaling etc. ) VFD 1. IR test. 2. Checking of earthing

functioning of various electrical schemes like aut change over, signaling etc. ) VFD 1. IR test. 2. Checking of earthing  connecti on earthing as per scheme. 3. Safety interlock checking, check ing of working of Em. Stop PB. 4. Functional/Circuit

connecti on earthing as per scheme. 3. Safety interlock checking, check ing of working of Em. Stop PB. 4. Functional/Circuit  wise test, heck operation of contactors fro local and remote/PLC modes from control room. 5. IO checking. 6. Setting of

wise test, heck operation of contactors fro local and remote/PLC modes from control room. 5. IO checking. 6. Setting of  all parameters /parameterization. 7. Idle running of VFD and motor for tuning/parameterization. 8. Testing and calibrati on of all meters. 9. Communication checking with plant automation. ) AUTOMATION SYSTEM 1. Network checking. 2. Checking of power supply & distribution. 3. Checking of electronic earthing system and proper earthing of ll panels/ electronics equipment as per manuals/manufacturers recommendat ion. 4. Checking of redundancy of network, CPU, Servers and other hardw are as per configuration drawing. 5. Checking of Software under simu lation, checking & modification of Graphics, Reports and correction/revision as required by process/site re quirement etc. 6. IO checking and rectification. 7. Checking of safety & process inte rlocks and correction as requi red by process/ site requirement, Checking of local & remote manual, auto mode of op eration, release of outputs, calibration etc. 8. PID loop setting, calibration. 9. Communication checking with all networking equipment as per con figuration drawing and establishment of communication with hird party equ ipment. 1. Check operation of contactors from local and remote/PLC modes rom control room HMI. 1. Safety interlock checking, check ing of working of Em. Stop PB. ) MOTORS 1. Insulation resistance (IR) test. 2. Continuity Test. 3. Checks for leveling, & fitment, Bolt tightness & other matching with mechani

all parameters /parameterization. 7. Idle running of VFD and motor for tuning/parameterization. 8. Testing and calibrati on of all meters. 9. Communication checking with plant automation. ) AUTOMATION SYSTEM 1. Network checking. 2. Checking of power supply & distribution. 3. Checking of electronic earthing system and proper earthing of ll panels/ electronics equipment as per manuals/manufacturers recommendat ion. 4. Checking of redundancy of network, CPU, Servers and other hardw are as per configuration drawing. 5. Checking of Software under simu lation, checking & modification of Graphics, Reports and correction/revision as required by process/site re quirement etc. 6. IO checking and rectification. 7. Checking of safety & process inte rlocks and correction as requi red by process/ site requirement, Checking of local & remote manual, auto mode of op eration, release of outputs, calibration etc. 8. PID loop setting, calibration. 9. Communication checking with all networking equipment as per con figuration drawing and establishment of communication with hird party equ ipment. 1. Check operation of contactors from local and remote/PLC modes rom control room HMI. 1. Safety interlock checking, check ing of working of Em. Stop PB. ) MOTORS 1. Insulation resistance (IR) test. 2. Continuity Test. 3. Checks for leveling, & fitment, Bolt tightness & other matching with mechani| Model Type | Helical gear Reduction Boxes H1 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 863.000000 |

| Ratio Range | 1 : 1.25…5.6 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 28700 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender France S.A.R.L. |

| Country of Manufacture | Bahamas |

| Data Sheet & Drawings | H1-SH-9B flendergetriebe Helical gear Reduction Boxes H1 |