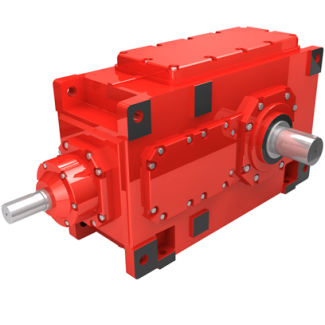

ash dual taper clamping connection RFK Hollow s B4VV-15-C Bevel-helical speed reducer B4

In stock

SKU

B4VV-15-C

$77,785.71

Flender/Flender Gear Units/Bevel-helical speed reducer B4

te wheat were obtained using transient line heat source method (Kazarian and Hall, .Bakke and Stiles (, Babbitt (, Moote (, Ojha et al. (, and Dua andOjah ( used steady-state heat-transfer equation in cylindrical coordinate to obtainthermal conductivity of

(, Ojha et al. (, and Dua andOjah ( used steady-state heat-transfer equation in cylindrical coordinate to obtainthermal conductivity of  grains. The transient methods have also been used to determinethermal conductivity of medium-grain, rough rice (Wratten et al., , beans,

grains. The transient methods have also been used to determinethermal conductivity of medium-grain, rough rice (Wratten et al., , beans,  corn, rape-seed (Pabis et al., , short-grain, rough rice (Morita and Singh, , sorghum (Miller, 1; Sharma and Thompson, ,

corn, rape-seed (Pabis et al., , short-grain, rough rice (Morita and Singh, , sorghum (Miller, 1; Sharma and Thompson, ,  hard, red, spring wheat (Chandra and Muir, , whole soybean, crushed soybean, powdered soybean (Jasonski and Bilanski, ,pigeon pea (Shephard and Bhardwaj, 1b), gram (Dutta et al., 1b). Dutta et al.(1b) reported that the thermal conductivity of gram increased with both increase intemperature and moisture content, and it was higher than that of pigeon pea, sorghum, or Properties of Cereal Grains 3 wheat, but lower than that of bean or corn. Thermal conductivity data for selected grains are summarized in Table 6. 3.3 Thermal Diffusivity Thermal diffusivity indicates how fast heat can propagate through the material under tran- sient conduction of heat-transfer conditions. Physically it relates the ability of material to conduct heat with its ability to store heat. The thermal diffusivity can be calculated bydividing the thermal conductivity by the product of specic heat and mass density: /H1k (Cp)( whereis thermal diffusivity (m2/);kis thermal conductivity (/ ); is density (kg/m, and Cpis specic heat (/kg ). Thermal diffusivity can be determined either by direct experiment or estimated from the thermal conductivity, specic heat, and densitydata. In the direct measurement, thermal diffusivity is based on the measured transienttemperatures at any location in the material being heated under known boundary condi- tions. The analytical solution to the Fouriers heat conduction equation in appropriate geometry or Heisler charts can be used to

hard, red, spring wheat (Chandra and Muir, , whole soybean, crushed soybean, powdered soybean (Jasonski and Bilanski, ,pigeon pea (Shephard and Bhardwaj, 1b), gram (Dutta et al., 1b). Dutta et al.(1b) reported that the thermal conductivity of gram increased with both increase intemperature and moisture content, and it was higher than that of pigeon pea, sorghum, or Properties of Cereal Grains 3 wheat, but lower than that of bean or corn. Thermal conductivity data for selected grains are summarized in Table 6. 3.3 Thermal Diffusivity Thermal diffusivity indicates how fast heat can propagate through the material under tran- sient conduction of heat-transfer conditions. Physically it relates the ability of material to conduct heat with its ability to store heat. The thermal diffusivity can be calculated bydividing the thermal conductivity by the product of specic heat and mass density: /H1k (Cp)( whereis thermal diffusivity (m2/);kis thermal conductivity (/ ); is density (kg/m, and Cpis specic heat (/kg ). Thermal diffusivity can be determined either by direct experiment or estimated from the thermal conductivity, specic heat, and densitydata. In the direct measurement, thermal diffusivity is based on the measured transienttemperatures at any location in the material being heated under known boundary condi- tions. The analytical solution to the Fouriers heat conduction equation in appropriate geometry or Heisler charts can be used to| Model Type | Bevel-helical speed reducer B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 3630.000000 |

| Ratio Range | 1 : 80…315 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 153000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Macneill Gears Ltd. |

| Country of Manufacture | Honduras |

| Data Sheet & Drawings | ash dual taper clamping connection RFK Hollow s B4VV-15-C Bevel-helical speed reducer B4 |