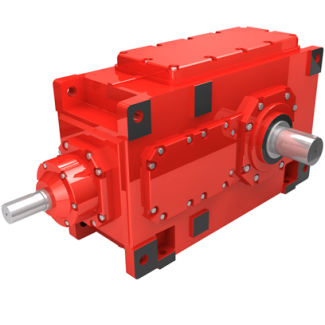

nd BD Type BD Hollow shaft with spline accord B4-VV-16-A Bevel-helical gear Reduction Box B4

In stock

SKU

B4-VV-16-A

$85,392.86

Flender/Flender Gear Units/Bevel-helical gear Reduction Box B4

te Agent License No.: CA0; SEBI Research Analyst Reg. No.: INH0; SEBI Investment Adviser Reg. No.: INA0; CIN - U6MH2PLC1 HDFC securities Institutional Equities Unit No. 1, 1th Floor, Tower , Peninsula Business Park, Senapati Bapat Marg, Lower Parel, Mumbai

HDFC securities Institutional Equities Unit No. 1, 1th Floor, Tower , Peninsula Business Park, Senapati Bapat Marg, Lower Parel, Mumbai  - 4 0 Board: +9 -2-6 -7 Germany hdfcsec HB series gearbox fact file CASE STUD NO TES DAn Drives

- 4 0 Board: +9 -2-6 -7 Germany hdfcsec HB series gearbox fact file CASE STUD NO TES DAn Drives  and AutomationAhlstrom Paper, Chirnside replace outdated line shaft cone pulley and belt drive system for modern ABB drive solution 3K

and AutomationAhlstrom Paper, Chirnside replace outdated line shaft cone pulley and belt drive system for modern ABB drive solution 3K  Variable Speed Drive project replaces an existing troublesome cone pulley and belt mechanically based speed control system, utilising ABB ACSM1 drives and Siemens Flender gearboxes. The paper mill, situated by the River Whiteadder, ( tributary of the River Tweed) was first built between 1 and 1 and then in 1 it was reconstructed by David Cousin for the Young Trotter Company. The railway line ran into the factory delivering esparto grass and china clay. It was owned by the Dexter Corporation until around 2 and is currently owned by the AHLSTROM-MUNKSJ Paper Group. Drives and Automation Ltd were awarded the contract to upgrade the existing 2 axis paper machine drive system, which was based on line shaft with cone pulleys and belts. The proposal was to convert the existing drive spindles into independent drives utilising AC geared motors and inverter control. The existing line shaft system required high levels of maintenance due to the considerable number of pulleys, belts, bearings and the hot steamy environment. Speed control accuracy was also an issue with belt slip, temperature change and operator set up errors. The new drive system comprised 2 No. ABB ACS M1 closed loop inverters with 2 No. ABB AC induction motors close coupled to Siemens Flender gear reducers, where necessary. The control panel was located in the existing substation but had to be purpose built, with back-to-back configuration, to fit within the available space. The drive control system

Variable Speed Drive project replaces an existing troublesome cone pulley and belt mechanically based speed control system, utilising ABB ACSM1 drives and Siemens Flender gearboxes. The paper mill, situated by the River Whiteadder, ( tributary of the River Tweed) was first built between 1 and 1 and then in 1 it was reconstructed by David Cousin for the Young Trotter Company. The railway line ran into the factory delivering esparto grass and china clay. It was owned by the Dexter Corporation until around 2 and is currently owned by the AHLSTROM-MUNKSJ Paper Group. Drives and Automation Ltd were awarded the contract to upgrade the existing 2 axis paper machine drive system, which was based on line shaft with cone pulleys and belts. The proposal was to convert the existing drive spindles into independent drives utilising AC geared motors and inverter control. The existing line shaft system required high levels of maintenance due to the considerable number of pulleys, belts, bearings and the hot steamy environment. Speed control accuracy was also an issue with belt slip, temperature change and operator set up errors. The new drive system comprised 2 No. ABB ACS M1 closed loop inverters with 2 No. ABB AC induction motors close coupled to Siemens Flender gear reducers, where necessary. The control panel was located in the existing substation but had to be purpose built, with back-to-back configuration, to fit within the available space. The drive control system| Model Type | Bevel-helical gear Reduction Box B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 3985.000000 |

| Ratio Range | 1 : 90…355 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 173000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | A. Fried. Flender AG |

| Country of Manufacture | Hungary |

| Data Sheet & Drawings | nd BD Type BD Hollow shaft with spline accord B4-VV-16-A Bevel-helical gear Reduction Box B4 |