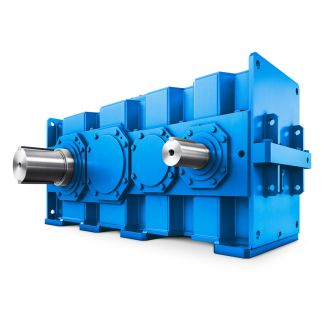

B4KV-11-C il filter visual or electronic monitoring devices Bevel-helical gear unit B4

In stock

SKU

B4KV-11-C

$31,821.43

Flender/Flender Gear Units/Bevel-helical gear unit B4

vated and interested in the improvement process Actions required in this step include the following: Assign the responsibility for tracking the progre ss of project and reporting on that progress. The staff responsible for progress reporting should also be allocated

the progre ss of project and reporting on that progress. The staff responsible for progress reporting should also be allocated  the resources necessary to fulfil their responsibilities. Review what is currently being measured and monitored Determine additional monitoring and measurements

the resources necessary to fulfil their responsibilities. Review what is currently being measured and monitored Determine additional monitoring and measurements  required on the prioritized ECMs Develop an & plan to maintain efficiency of ae ration equipment .. diffuser cleaning, sensor

required on the prioritized ECMs Develop an & plan to maintain efficiency of ae ration equipment .. diffuser cleaning, sensor  cleaning and calibration, motor servicing etc. Regularly review progress of energy targets and monitor compliance Implement corrective actions to stay on target Regularly communicate with staff and all stakeholders Set the performance metrics that will be used. Create communication plan. The plan should identify who needs to be included in progress reports (.. elected officials, public, etc.), wh en reports should be made, and any actions that need to occur in response to reports. Key points to Consider 3.3.8 Step 8: Maintain and Expand EMPs within the whole Organization The previous steps have shown how to implement, in systematic way an EMP to minimize aeration energy use at activated sludge plants for typical municipality. For municipalities with number of plants, the program would initially be applied to few plants before expanding to others. It is therefore important to maintain the success of the initial EMP and then expand it to other plants and other areas of water and wastewater management. Recommended Actions: Continue to align energy goals with business and operational goals and strategies Revise energy goals to match changes in business policies and/ or regulatory requirements Apply lessons learnt to improve execution of new EMPs Performance metrics need to be focused so that only those benefits that can be directly attributed to project ar

cleaning and calibration, motor servicing etc. Regularly review progress of energy targets and monitor compliance Implement corrective actions to stay on target Regularly communicate with staff and all stakeholders Set the performance metrics that will be used. Create communication plan. The plan should identify who needs to be included in progress reports (.. elected officials, public, etc.), wh en reports should be made, and any actions that need to occur in response to reports. Key points to Consider 3.3.8 Step 8: Maintain and Expand EMPs within the whole Organization The previous steps have shown how to implement, in systematic way an EMP to minimize aeration energy use at activated sludge plants for typical municipality. For municipalities with number of plants, the program would initially be applied to few plants before expanding to others. It is therefore important to maintain the success of the initial EMP and then expand it to other plants and other areas of water and wastewater management. Recommended Actions: Continue to align energy goals with business and operational goals and strategies Revise energy goals to match changes in business policies and/ or regulatory requirements Apply lessons learnt to improve execution of new EMPs Performance metrics need to be focused so that only those benefits that can be directly attributed to project ar| Model Type | Bevel-helical gear unit B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1485.000000 |

| Ratio Range | 1 : 80…315 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 61600 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Guss Gmbh & Co. Kg |

| Country of Manufacture | United States |

| Data Sheet & Drawings | B4KV-11-C il filter visual or electronic monitoring devices Bevel-helical gear unit B4 |