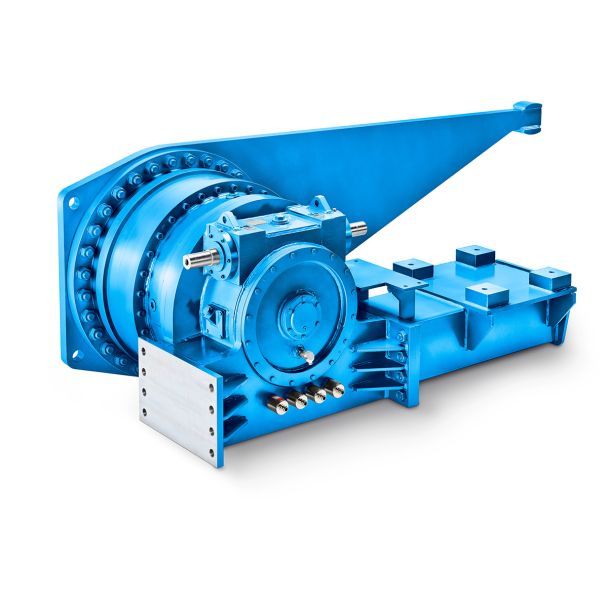

Bevel-helical gearboxes B4 can be achieved A labyrinth system filled with s B4HH-14-C

In stock

SKU

B4HH-14-C

$58,607.14

Flender/Flender Gear Units/Bevel-helical gearboxes B4

tion from both central control room and/or from remote locations Increased transparency thanks to management information using protocol and statistics functions as well as long-term archiving Efficient and simple opera- tion is the key to success The visualization of process

functions as well as long-term archiving Efficient and simple opera- tion is the key to success The visualization of process  data fol- lows the respective predetermined process hierarchy and structure. For example, simple block icon in the display shows the

data fol- lows the respective predetermined process hierarchy and structure. For example, simple block icon in the display shows the  status, operation mode, plant identifier and the most important values for each component. The visual navigation reflects the tech-nological hierarchy

status, operation mode, plant identifier and the most important values for each component. The visual navigation reflects the tech-nological hierarchy  of the plant and shows summary of alarms and warn-ings from substructures. This means that complete process groups can be started and stopped at the click of mouse, for example when restarting specific process. An object browser makes it possible to identify and dis- play all objects within the plant in certain operational phase for exam-ple In simulation. Process values such as pressure or flow rate can be used for the feedback signal Drive on. This considerably increases the quality of information on the correct functional- ity of the drive. The additional new operational mode Out of service is used for components and aggregates that are not available, for example, due to maintenance or service.With the Minerals Automation Stan- dard, Siemens sets the benchmark for high-performance automation, cost-effective operation and an efficient lifecycle management for the mining industry. Each library object covers PLC program block and visualization modulesAn integrated power control system for the mining industry combines pro- cess and power control on the basis of the IEC 6 standard. Using library-based dashboard in the optional Energy Management Sys- tem, the operator can get information on the energy data in the main and aux-iliary systems. The display of key perfor - mance indicators helps reduce energy costs and ensures timely reaction, if required. The data is available to plant

of the plant and shows summary of alarms and warn-ings from substructures. This means that complete process groups can be started and stopped at the click of mouse, for example when restarting specific process. An object browser makes it possible to identify and dis- play all objects within the plant in certain operational phase for exam-ple In simulation. Process values such as pressure or flow rate can be used for the feedback signal Drive on. This considerably increases the quality of information on the correct functional- ity of the drive. The additional new operational mode Out of service is used for components and aggregates that are not available, for example, due to maintenance or service.With the Minerals Automation Stan- dard, Siemens sets the benchmark for high-performance automation, cost-effective operation and an efficient lifecycle management for the mining industry. Each library object covers PLC program block and visualization modulesAn integrated power control system for the mining industry combines pro- cess and power control on the basis of the IEC 6 standard. Using library-based dashboard in the optional Energy Management Sys- tem, the operator can get information on the energy data in the main and aux-iliary systems. The display of key perfor - mance indicators helps reduce energy costs and ensures timely reaction, if required. The data is available to plant| Model Type | Bevel-helical gearboxes B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 2735.000000 |

| Ratio Range | 1 : 100…400 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 113000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | WALTHER FLENDER GMBH |

| Country of Manufacture | Belgium |

| Data Sheet & Drawings | Bevel-helical gearboxes B4 can be achieved A labyrinth system filled with s B4HH-14-C |