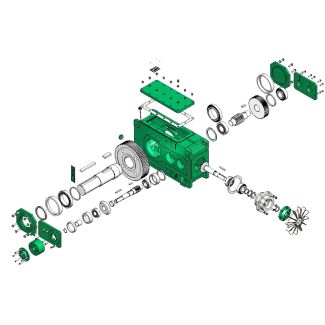

on dimensions Solid shaft with parallel key Types B4CH-6-C Bevel-helical gearboxes B4

In stock

SKU

B4CH-6-C

$8,250.00

Flender/Flender Gear Units/Bevel-helical gearboxes B4

ters are optimised in Matlab using expectation maximisation (EM) so as to maximise the likelihood of the observed data. good reference on the topic of expectation maximisation is provided by Bishop [1]. The EM algorithm is initialised by centring the

reference on the topic of expectation maximisation is provided by Bishop [1]. The EM algorithm is initialised by centring the  GMM components on randomly selected samples from the training set. The EM algorithm is not guaranteed to nd the global

GMM components on randomly selected samples from the training set. The EM algorithm is not guaranteed to nd the global  optimum, so that it is expected that the performance from different optimisation runs will differ slightly. The EM optimisation step

optimum, so that it is expected that the performance from different optimisation runs will differ slightly. The EM optimisation step  is thus repeated number of times, and the solution which offers the best results is subsequently selected. Conditional density distributions Occasionally the operating conditions (or at least covariates which partially describe the operating conditions) may be measured. It may then be possible to use the knowledge of the operating conditions to rene the computed NLL values. This may be done by conditioning the outcome of the observed signal segment on the measured operating conditions. This should render the computed NLL values more robust to time-varying operating conditions, and subsequently more sensitive to fault induced signal outliers. Consider for example that the shaft angular speed (as possibly estimated from the tachometer) may occasionally be proportional to the applied torque on gearbox. The angular speed may subsequently co-vary (possibly in non-linear manner) with the amplitude or phase modulation of signal segment. As previously dened the column vector siis used to represent single signal segment. Let cirepresent the column vector which contains variables which are representative of the observed operating conditions which corresponds to the period during which the segment siis measured. The operating conditions vector cimay for example contain one entry which represents the mean angular velocity and different one which describes the applied load. The likelihood of signal segment sias conditioned on the vector describing the associated operating cond

is thus repeated number of times, and the solution which offers the best results is subsequently selected. Conditional density distributions Occasionally the operating conditions (or at least covariates which partially describe the operating conditions) may be measured. It may then be possible to use the knowledge of the operating conditions to rene the computed NLL values. This may be done by conditioning the outcome of the observed signal segment on the measured operating conditions. This should render the computed NLL values more robust to time-varying operating conditions, and subsequently more sensitive to fault induced signal outliers. Consider for example that the shaft angular speed (as possibly estimated from the tachometer) may occasionally be proportional to the applied torque on gearbox. The angular speed may subsequently co-vary (possibly in non-linear manner) with the amplitude or phase modulation of signal segment. As previously dened the column vector siis used to represent single signal segment. Let cirepresent the column vector which contains variables which are representative of the observed operating conditions which corresponds to the period during which the segment siis measured. The operating conditions vector cimay for example contain one entry which represents the mean angular velocity and different one which describes the applied load. The likelihood of signal segment sias conditioned on the vector describing the associated operating cond| Model Type | Bevel-helical gearboxes B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 385.000000 |

| Ratio Range | 1 : 100…400 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 15500 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. Friedr. Flender GmbH |

| Country of Manufacture | Russia |

| Data Sheet & Drawings | on dimensions Solid shaft with parallel key Types B4CH-6-C Bevel-helical gearboxes B4 |