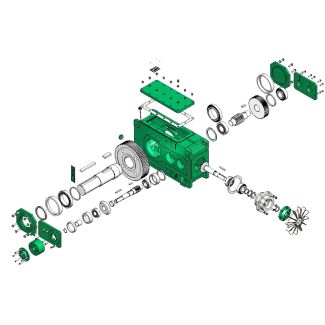

GMDEN I G IGdd Selection of fit see page Fle B4-CH-6-D Bevel-helical gear boxes B4

In stock

SKU

B4-CH-6-D

$8,250.00

Flender/Flender Gear Units/Bevel-helical gear boxes B4

ters established for that grade. Grading may be dened as the segregation of heterogeneous material into series of grades reecting different quality characteristicsof signicance to the users (Canada Grains Council, . The quality of grain is an important factor that

different quality characteristicsof signicance to the users (Canada Grains Council, . The quality of grain is an important factor that  affects the price customers or end users are willing to pay. The requirements differ widely based on end use, such

affects the price customers or end users are willing to pay. The requirements differ widely based on end use, such  as high- 4 Hulasare et al. protein wheat for baking pan breads, or low-protein wheat for noodles and at breads.

as high- 4 Hulasare et al. protein wheat for baking pan breads, or low-protein wheat for noodles and at breads.  Other factors such as foreign material content, uniformity within and between shipments,dockage, and moisture content also determine the quality and the price. Ideally, gradingsystem should take into account the customer preference (end users) and also ensure equi-table returns to the producers. Grading systems of exporting countries are revised regularly to adapt to changing global trade in grains (trade without borders or various international trade treaties), customer preferences, and logistics of grain movement over distances. Grading is the segregation of grain into parcels of dened quality to facilitate price determination (Canadian Grain Commission [CGC], . successful grain-gradingsystem must achieve the following results: 1. Assure the producer an equitable grain price relative to its quality. 2. Facilitate grain handling by encouraging the collective storage of bulk lots of similar quality. 3. Establish method of relating prices to quality to simplify trading.4. Enable the buyer to consistently obtain the same quality of grain.5. Separate grain into sufcient number of quality divisions so that the buyers have choice of grades, but at the same time, limit the number of grades to facilitate handling and storing in an efcient bulk-handling system. In this chapter, brief history of the development of grading systems is presented. The Canadian-grading system is described in detail, using wheat as an example, and iscompared with the United States- and Australian-gradin

Other factors such as foreign material content, uniformity within and between shipments,dockage, and moisture content also determine the quality and the price. Ideally, gradingsystem should take into account the customer preference (end users) and also ensure equi-table returns to the producers. Grading systems of exporting countries are revised regularly to adapt to changing global trade in grains (trade without borders or various international trade treaties), customer preferences, and logistics of grain movement over distances. Grading is the segregation of grain into parcels of dened quality to facilitate price determination (Canadian Grain Commission [CGC], . successful grain-gradingsystem must achieve the following results: 1. Assure the producer an equitable grain price relative to its quality. 2. Facilitate grain handling by encouraging the collective storage of bulk lots of similar quality. 3. Establish method of relating prices to quality to simplify trading.4. Enable the buyer to consistently obtain the same quality of grain.5. Separate grain into sufcient number of quality divisions so that the buyers have choice of grades, but at the same time, limit the number of grades to facilitate handling and storing in an efcient bulk-handling system. In this chapter, brief history of the development of grading systems is presented. The Canadian-grading system is described in detail, using wheat as an example, and iscompared with the United States- and Australian-gradin| Model Type | Bevel-helical gear boxes B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 385.000000 |

| Ratio Range | 1 : 100…400 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 15500 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | flanders electric peru s a c |

| Country of Manufacture | China |

| Data Sheet & Drawings | GMDEN I G IGdd Selection of fit see page Fle B4-CH-6-D Bevel-helical gear boxes B4 |