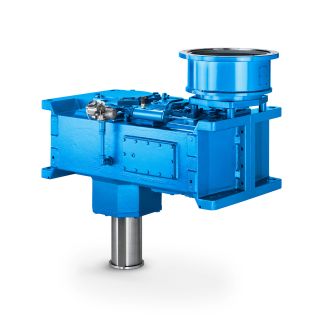

tens ion for shaft extension at both ends Selectio B4-VV-26-A Bevel-helical speed reducer B4

In stock

SKU

B4-VV-26-A

$385,714.29

Flender/Flender Gear Units/Bevel-helical speed reducer B4

tended Total Centre Distance Key to Symbols Siemens MD K2-1 2/2 P1 = 7 kW n1 = 1 1/min TA = 1 Nm P2 = 6 kW n2 = 2 /min 1 / FEM L3T8 - M8 2 ED =

= 1 Nm P2 = 6 kW n2 = 2 /min 1 / FEM L3T8 - M8 2 ED =  4% 3 ( 4 / ) erf 7 mm d2 1. 1.1 1.2 K4 9 PN = 1 kW =

4% 3 ( 4 / ) erf 7 mm d2 1. 1.1 1.2 K4 9 PN = 1 kW =  8 mm K3: = 6 mm < Eerf = 7 mm 1.3 2. 2.1 K4 Known criteria: PRIME MOVER Electric

8 mm K3: = 6 mm < Eerf = 7 mm 1.3 2. 2.1 K4 Known criteria: PRIME MOVER Electric  motor P1 = 7 kW Motor speed n1 = 1 1/min Max. starting torque TA = 1 Nm DRIVEN MACHINE Hoisting gear P2 = 6 kW Speed n2 = 2 /min Duty 1 / dayClassi cation acc. to FEM L3T8 - M8 Starts per hour 2Operating cycle per hour = 4% Ambient temperature 3 CInstallation in large hall ( 4 /)Altitude sea level GEAR UNIT DESIGN Helical gear unitMounting position: horizontalInput and output shaft arranged on one side. Minimum total centre distance erf 7 mm, design Direction of rotation of output shaft d2: ccw Required: Type and size of gear unit 1. Selection of gear unit type and size 1.1 Calculation of transmission ratio 1.2 Determination of the gear unit nominal power rating Selected from power rating table: type K4, gear unit size 9, with = 1 kW and total centre distance = 8 mm. (Type K3: = 6 mm < erf = 7 mm) 1.3 Checking the starting torque 2. Determination of thermal capacity 2.1 Thermal capacity for gear units without auxiliary cooling, acc. to table for type K4 gear unit without auxiliary cooling is suf cient!PG = PG1 f4 f6 f8 f9 PG = 1 kW 1.8 1 1 0.9 = 1.4 kW P2 = 6 kW < PG = 1.4 kWPN TA n1 f3 = 1 1 0.8 = 9.0 kW PN = 1 kW > 9.0 kW 9 9 3.3 P2 PN 3.3 6 = 2.8 kW > PN It is not necessary to consult usPN P2 f1 f2 = 6 1.4 1 = 9.4 kWis = n1 = 1 = 3.7 iN = 3.5 n2 2 Helical Gear Units With Extended Total Centre Distance Guidelines for the Selection Calculation Example Siemens MD K2-1 2/2 FEM f1 f3 M1 ... M8 1 L1 ... L4 T0 ... T9 9 2 P1 ... PN t1 ...tn

motor P1 = 7 kW Motor speed n1 = 1 1/min Max. starting torque TA = 1 Nm DRIVEN MACHINE Hoisting gear P2 = 6 kW Speed n2 = 2 /min Duty 1 / dayClassi cation acc. to FEM L3T8 - M8 Starts per hour 2Operating cycle per hour = 4% Ambient temperature 3 CInstallation in large hall ( 4 /)Altitude sea level GEAR UNIT DESIGN Helical gear unitMounting position: horizontalInput and output shaft arranged on one side. Minimum total centre distance erf 7 mm, design Direction of rotation of output shaft d2: ccw Required: Type and size of gear unit 1. Selection of gear unit type and size 1.1 Calculation of transmission ratio 1.2 Determination of the gear unit nominal power rating Selected from power rating table: type K4, gear unit size 9, with = 1 kW and total centre distance = 8 mm. (Type K3: = 6 mm < erf = 7 mm) 1.3 Checking the starting torque 2. Determination of thermal capacity 2.1 Thermal capacity for gear units without auxiliary cooling, acc. to table for type K4 gear unit without auxiliary cooling is suf cient!PG = PG1 f4 f6 f8 f9 PG = 1 kW 1.8 1 1 0.9 = 1.4 kW P2 = 6 kW < PG = 1.4 kWPN TA n1 f3 = 1 1 0.8 = 9.0 kW PN = 1 kW > 9.0 kW 9 9 3.3 P2 PN 3.3 6 = 2.8 kW > PN It is not necessary to consult usPN P2 f1 f2 = 6 1.4 1 = 9.4 kWis = n1 = 1 = 3.7 iN = 3.5 n2 2 Helical Gear Units With Extended Total Centre Distance Guidelines for the Selection Calculation Example Siemens MD K2-1 2/2 FEM f1 f3 M1 ... M8 1 L1 ... L4 T0 ... T9 9 2 P1 ... PN t1 ...tn| Model Type | Bevel-helical speed reducer B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 18000.000000 |

| Ratio Range | 1 : 90…355 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 1030000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender (Australia) Pty. Ltd. |

| Country of Manufacture | Nicaragua |

| Data Sheet & Drawings | tens ion for shaft extension at both ends Selectio B4-VV-26-A Bevel-helical speed reducer B4 |