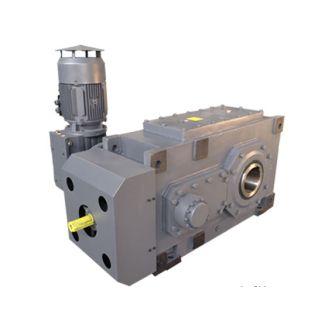

Bevel-helical gear box B4 rds Flender GmbH Flender MD Bevel helical g B4-SV-28-A

In stock

SKU

B4-SV-28-A

$561,428.57

Flender/Flender Gear Units/Bevel-helical gear box B4

suring compliance with final effluent quality requirements. Oxygen demand for aeration is proportional to the organic and ammonia load into the plant and these fluctuate with time of day and sometimes on weekly and seasonal basis depending on the plant.

the plant and these fluctuate with time of day and sometimes on weekly and seasonal basis depending on the plant.  The two most important operating parameters in activated sludge .. sludge retention time (SRT)/sludge age) and dissolved oxygen (DO) not

The two most important operating parameters in activated sludge .. sludge retention time (SRT)/sludge age) and dissolved oxygen (DO) not  only impact process performance but also aeration energy requirements. Implementing optimum process operating parameters as well as automatic aeration control

only impact process performance but also aeration energy requirements. Implementing optimum process operating parameters as well as automatic aeration control  systems results in substantial saving in aeration energy. Usually, plant operating parameters are set based on design guidelines (which are typically conservative) or on historic or conventional practices thus optimization after commissioning will ensure optimum energy use. Therefore energy savings can be gained by design ing and operating aeration systems to match, as closely as possible, the actual oxygen demands of th process. By understanding the oxygen demands of their particular wastewater and how those demands vary daily, weekly and seasonally wastewater treatment plants (WWTPs) can implement process and aeration systems control strategies that can ensure long term efficient energy use. 1-5 1.2.3 The Role of Advanced Process Modelling in Evaluating Energy Conservation Measures for Aeration Systems The last two decades has seen not only the introduc tion of very sophisticated and accurate biological models for activated sludge processes .. ASM1, ASM2 (Gujer, , ASM2d (Henze, and ASM3 (Gujer but also commercial simulation progra ms (simulators) that incorporate the biological models as well as other treatment units at WWTP (.. BIOWIN, GPSX, WEST, SIMBA). These tools have been proven to be very useful for design, research and optimization of WWTP and their application has been increasing over the years. At the same time, automation process control technologies have been developing rap

systems results in substantial saving in aeration energy. Usually, plant operating parameters are set based on design guidelines (which are typically conservative) or on historic or conventional practices thus optimization after commissioning will ensure optimum energy use. Therefore energy savings can be gained by design ing and operating aeration systems to match, as closely as possible, the actual oxygen demands of th process. By understanding the oxygen demands of their particular wastewater and how those demands vary daily, weekly and seasonally wastewater treatment plants (WWTPs) can implement process and aeration systems control strategies that can ensure long term efficient energy use. 1-5 1.2.3 The Role of Advanced Process Modelling in Evaluating Energy Conservation Measures for Aeration Systems The last two decades has seen not only the introduc tion of very sophisticated and accurate biological models for activated sludge processes .. ASM1, ASM2 (Gujer, , ASM2d (Henze, and ASM3 (Gujer but also commercial simulation progra ms (simulators) that incorporate the biological models as well as other treatment units at WWTP (.. BIOWIN, GPSX, WEST, SIMBA). These tools have been proven to be very useful for design, research and optimization of WWTP and their application has been increasing over the years. At the same time, automation process control technologies have been developing rap| Model Type | Bevel-helical gear box B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 26200.000000 |

| Ratio Range | 1 : 90…355 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 1400000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender (Australia) Pty. Ltd. |

| Country of Manufacture | Liechtenstein |

| Data Sheet & Drawings | Bevel-helical gear box B4 rds Flender GmbH Flender MD Bevel helical g B4-SV-28-A |