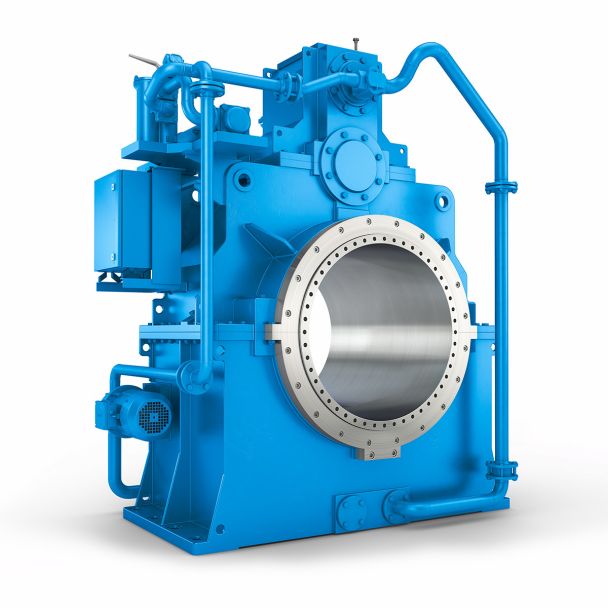

Bevel-helical speed reducers B4 extension shown represents the driven machine sha B4-SV-26-D

In stock

SKU

B4-SV-26-D

$385,714.29

Flender/Flender Gear Units/Bevel-helical speed reducers B4

sure turbo-generators of the sugar factory, the output of the fifth boiler will go to 1 MW condensing turbo-generator, the "Turbo Aleman", wl:Ich, along with its condenser, cooling tower, and pumps, has been stored on the premises since 1. The

"Turbo Aleman", wl:Ich, along with its condenser, cooling tower, and pumps, has been stored on the premises since 1. The  "Turbo Aleman" has two extraction studs, one for 4 per hour at 2 psig, and one for 7 per hour

"Turbo Aleman" has two extraction studs, one for 4 per hour at 2 psig, and one for 7 per hour  at 1 psig. This may have been specified with the no longer current distillery in mind. The exhaust steam from

at 1 psig. This may have been specified with the no longer current distillery in mind. The exhaust steam from  the three backpressure turbines will go to the sugar factory process vessels during the crop. During the off-crop it will drive condensing turbine, coupled to 1.6 MW generator, the "Turbo Sueco". This machine and its accessories, manufactured by ASEA, have also been stored at the mill for six years. The factory spray-pond will be used to cool the condenser water for the off-crop-only operation of this unit. On the electrical side, both of the new generators will be connected to the 1.8 kV buzz bar, the "Turbo Sueco" directly and the "Turbo Aleman", generating at 6.3 MV, through 1.8/6.3 kV transformer. Tied into the 1.8 kV bar, there will be Victoria de Julio' external distribution grid supplying the agricultural sector. The 1.8 kV bar, also will absorb the excess power from the factory generators, and from it, INE will receive, at stepped-up voltage, any commercially handled electr icity. All the necessary transformers and switchgear are on the premises. During the crop, with an average 6,0 tpd grinding rate, the three backpressure machines and the "Turbo Aleman" will generate an average of 2 MW. Of this, 7 MW will be required by the factory and 8 MW by the field, leaving 5 MW to be sold to INE. The fuel needed to satisfy the field and factory demands for electrical energy, in addition to the factory demand for thermal energy, and for having 5 MW available for sale, amounts to the baga ,se supplied by the cane, supplemented by 2 of wood chips or 8 (2,0 gal) of fuel oil per day, or any proportio

the three backpressure turbines will go to the sugar factory process vessels during the crop. During the off-crop it will drive condensing turbine, coupled to 1.6 MW generator, the "Turbo Sueco". This machine and its accessories, manufactured by ASEA, have also been stored at the mill for six years. The factory spray-pond will be used to cool the condenser water for the off-crop-only operation of this unit. On the electrical side, both of the new generators will be connected to the 1.8 kV buzz bar, the "Turbo Sueco" directly and the "Turbo Aleman", generating at 6.3 MV, through 1.8/6.3 kV transformer. Tied into the 1.8 kV bar, there will be Victoria de Julio' external distribution grid supplying the agricultural sector. The 1.8 kV bar, also will absorb the excess power from the factory generators, and from it, INE will receive, at stepped-up voltage, any commercially handled electr icity. All the necessary transformers and switchgear are on the premises. During the crop, with an average 6,0 tpd grinding rate, the three backpressure machines and the "Turbo Aleman" will generate an average of 2 MW. Of this, 7 MW will be required by the factory and 8 MW by the field, leaving 5 MW to be sold to INE. The fuel needed to satisfy the field and factory demands for electrical energy, in addition to the factory demand for thermal energy, and for having 5 MW available for sale, amounts to the baga ,se supplied by the cane, supplemented by 2 of wood chips or 8 (2,0 gal) of fuel oil per day, or any proportio| Model Type | Bevel-helical speed reducers B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 18000.000000 |

| Ratio Range | 1 : 90…355 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 1030000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Corporation |

| Country of Manufacture | Kyrgyzstan |

| Data Sheet & Drawings | Bevel-helical speed reducers B4 extension shown represents the driven machine sha B4-SV-26-D |