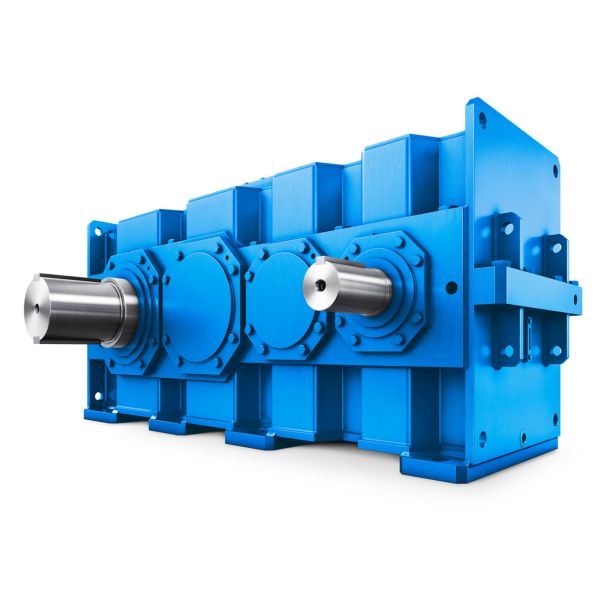

Bevel-helical speed reducer B4 table for minimum input speed n required for dip B4-HV21A

In stock

SKU

B4-HV21A

$197,142.86

Flender/Flender Gear Units/Bevel-helical speed reducer B4

trations are much lower than the current measured values as well as those predicted with optimised process control in Section 4.7.1. 5.7.3 Complex High Capital Investment Measures Replace Existing Surface Aerators The evaluation was carried out for replacing existing surface

4.7.1. 5.7.3 Complex High Capital Investment Measures Replace Existing Surface Aerators The evaluation was carried out for replacing existing surface  aerators with: FBDA with membrane diffusers and turbo blowers Hybrid aerator/mixer Model simulations were carried out with both traditional feedback

aerators with: FBDA with membrane diffusers and turbo blowers Hybrid aerator/mixer Model simulations were carried out with both traditional feedback  DO as well as advanced process control strategies. 5-2 Table 5-1 summarises the model predicted energy and cost savings that

DO as well as advanced process control strategies. 5-2 Table 5-1 summarises the model predicted energy and cost savings that  can be achieved with these two measures. Table 5-1: JP Marais WWTP Model Predicted Energy and Cost Savings for Replacing Surface Aerators with More Efficient Systems Units Baseline FBDA Hybrid Aerator/Mixer FB DO FB Cascade NH 4+/DO FF/FB NH 4+/DO FB Cascade NH 4+/DO Consumption MWh/yr 2,4,0 1,7, 0 1,6,3 1,5,1 1,4,4 Consumption Saving MWh/yr 7,9 8,6 8,9 9,6 % Consumption Saving % 3 3 3 3 Consumption Cost /yr 2,2,4 1,5 9,7 1,5,8 1,4,0 1,3,7 Consumption Cost Saving /yr 6,6 7,5 8,3 9,7 % Consumption Cost Saving % 3 3 3 3 Demand Saving kW 8 9 9 1 Final Effluent Quality* FSA mgN/ 1 1 3.5 3.5 3.5 Ortho mgP/ 0.3 0.2 0.0 0.0 0.0 Nitrate/Nitrite mgN/ 1 4 3 3 3 With FBDA potential energy consumption and cost savings of 3-3% can be realised depending on the aeration control strategy adopted. The hybrid aerato / mixer which has been assumed to have higher energy efficiency than FBDA can potentially save 3% of energy consumption and cost. Demand savings of 8-1 kW can also be potentially realis ed as result of consumption savings. 5.7.4 Comparison of Feasible ECMs summary of the financial analysis for implementing the feasible aeration ECMs is presented in Table 5-1. The same methodology outlined in Section 4.7.4 for Zeekoegat WWTP was followed. Costs for fine bubble diffusers, blowers and control system were obtained from local suppliers.

can be achieved with these two measures. Table 5-1: JP Marais WWTP Model Predicted Energy and Cost Savings for Replacing Surface Aerators with More Efficient Systems Units Baseline FBDA Hybrid Aerator/Mixer FB DO FB Cascade NH 4+/DO FF/FB NH 4+/DO FB Cascade NH 4+/DO Consumption MWh/yr 2,4,0 1,7, 0 1,6,3 1,5,1 1,4,4 Consumption Saving MWh/yr 7,9 8,6 8,9 9,6 % Consumption Saving % 3 3 3 3 Consumption Cost /yr 2,2,4 1,5 9,7 1,5,8 1,4,0 1,3,7 Consumption Cost Saving /yr 6,6 7,5 8,3 9,7 % Consumption Cost Saving % 3 3 3 3 Demand Saving kW 8 9 9 1 Final Effluent Quality* FSA mgN/ 1 1 3.5 3.5 3.5 Ortho mgP/ 0.3 0.2 0.0 0.0 0.0 Nitrate/Nitrite mgN/ 1 4 3 3 3 With FBDA potential energy consumption and cost savings of 3-3% can be realised depending on the aeration control strategy adopted. The hybrid aerato / mixer which has been assumed to have higher energy efficiency than FBDA can potentially save 3% of energy consumption and cost. Demand savings of 8-1 kW can also be potentially realis ed as result of consumption savings. 5.7.4 Comparison of Feasible ECMs summary of the financial analysis for implementing the feasible aeration ECMs is presented in Table 5-1. The same methodology outlined in Section 4.7.4 for Zeekoegat WWTP was followed. Costs for fine bubble diffusers, blowers and control system were obtained from local suppliers.| Model Type | Bevel-helical speed reducer B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 9200.000000 |

| Ratio Range | 1 : 80…315 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 420000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | F. H. Transmissiones S.A |

| Country of Manufacture | Suriname |

| Data Sheet & Drawings | Bevel-helical speed reducer B4 table for minimum input speed n required for dip B4-HV21A |