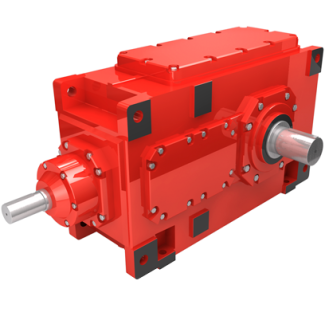

B4-FV-13-D ation Enclosed room or building with gates G Bui Bevel-helical speed reduction gearbox B4

In stock

SKU

B4-FV-13-D

$51,321.43

Flender/Flender Gear Units/Bevel-helical speed reduction gearbox B4

y Milling 3 has helped it to secure an important place in the breakfast cereals group and other pro- cessed food. The milling process of oats is very different from the rest of the cereal grains. This is primarily for

food. The milling process of oats is very different from the rest of the cereal grains. This is primarily for  three reasons: 1. The hulls strongly adhere to the kernel or groat. 2. Owing to their high fat content, the

three reasons: 1. The hulls strongly adhere to the kernel or groat. 2. Owing to their high fat content, the  oat kernels need to be stabilized through heat treatment for prevention of rancidity. 3. The form of its consumption is

oat kernels need to be stabilized through heat treatment for prevention of rancidity. 3. The form of its consumption is  quite different from the rest. 3.2 Quality of Oats Selection criteria of quality of oats for milling requirements are as follows: Low moisture content. Clean as possible and, particularly, freedom from wild oats, barley, and other seeds of similar length and density that are hard to remove. Low tolerance for discolored kernels as well as uniform kernel size are very impor- tant. High test weight (bulk density) for thin seeds and higher percentage of hulls reduce yields and cause processing problems. Low tolerance for immature, light oat kernels that would affect the yield and also would be hard to remove. 3.3 Milling Process The milling process begins with cleaning the oats. Cleaning is followed by grading before dehulling. Dehulling operations remove the hulls, and oat kernels without the hulls (groats)are sent for conditioning and drying. The conditioned groats are then graded and subse-quently sent for cutting or aking. Some of this material may also be ground and sifted foroat our and bran production, discussed later in some detail. The sequence of operations inmodern oat-processing plants is generally very similar to what is shown in Fig. 2. Fig. 2 simplied block ow diagram of oat-milling process. 3 Sarkar The cleaning system for oats uses equipment similar to that seen in the cleaning house of the other cereal grain-milling systems, except the clipper. 3.3.1 CleaningThe cleaning of oats begins with weighing scale, followed by magnet for removal of any ferrous metal or its alloy from the oat stream. The rst cleaning mach

quite different from the rest. 3.2 Quality of Oats Selection criteria of quality of oats for milling requirements are as follows: Low moisture content. Clean as possible and, particularly, freedom from wild oats, barley, and other seeds of similar length and density that are hard to remove. Low tolerance for discolored kernels as well as uniform kernel size are very impor- tant. High test weight (bulk density) for thin seeds and higher percentage of hulls reduce yields and cause processing problems. Low tolerance for immature, light oat kernels that would affect the yield and also would be hard to remove. 3.3 Milling Process The milling process begins with cleaning the oats. Cleaning is followed by grading before dehulling. Dehulling operations remove the hulls, and oat kernels without the hulls (groats)are sent for conditioning and drying. The conditioned groats are then graded and subse-quently sent for cutting or aking. Some of this material may also be ground and sifted foroat our and bran production, discussed later in some detail. The sequence of operations inmodern oat-processing plants is generally very similar to what is shown in Fig. 2. Fig. 2 simplied block ow diagram of oat-milling process. 3 Sarkar The cleaning system for oats uses equipment similar to that seen in the cleaning house of the other cereal grain-milling systems, except the clipper. 3.3.1 CleaningThe cleaning of oats begins with weighing scale, followed by magnet for removal of any ferrous metal or its alloy from the oat stream. The rst cleaning mach| Model Type | Bevel-helical speed reduction gearbox B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 2395.000000 |

| Ratio Range | 1 : 80…315 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 90700 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Ibérica S.A. |

| Country of Manufacture | Cambodia |

| Data Sheet & Drawings | B4-FV-13-D ation Enclosed room or building with gates G Bui Bevel-helical speed reduction gearbox B4 |