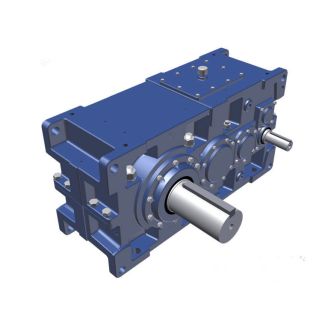

Bevel-helical gear boxes B4 to Order code Article No LP Z Perm B4-FV-11B

In stock

SKU

B4-FV-11B

$31,821.43

Flender/Flender Gear Units/Bevel-helical gear boxes B4

y damage Damage to the gear unit is possible. Immediately stop the gear unit by turning off the drive unit when inexplicable changes are noticedduring the operation, such as significantly increased operating temperature or changed sounds of the gear unit.

when inexplicable changes are noticedduring the operation, such as significantly increased operating temperature or changed sounds of the gear unit.  DANGER Danger to life by rotating and/or moving parts Risk of being gripped or drawn in by rotating and/or moving

DANGER Danger to life by rotating and/or moving parts Risk of being gripped or drawn in by rotating and/or moving  parts. Rotating and/or movable drive parts must be fitted with suitable safeguards to prevent contact. Note When the gear unit

parts. Rotating and/or movable drive parts must be fitted with suitable safeguards to prevent contact. Note When the gear unit  is incorporated in plant or machinery, the manufacturer of such plant or machinerymust ensure that the prescriptions, notes and descriptions contained in these instructions areincorporated in his own instructions. Removed safety equipment must be re-fitted prior to starting up. Notices attached to the gear unit, such as rating plate and direction arrow, must always be observed. They must be kept free from dirt and paint at all times. Missing plates must be replaced. Screws which have been damaged during assembly or disassembly work must be replaced with new ones of the same strength class and type. Spare parts must be obtained from Siemens (see section 1. "Spare parts, customer service"). 3.2 Environmental protection Dispose of any packaging material in accordance with regulations or separate it for recycling. When changing oil, the used oil must be collected in suitable containers. Remove any pools of oil immediately using an oil binding agent. Preservative agents should be stored separately from used oil. Used oil, preservative agents, oil binding agents and oil-soaked cloths must be disposed of in accordance with environmental legislation. Disposal of the gear unit after its useful life: Drain all the operating oil, preservative agent and/or cooling agent from the gear unit and dispose of in accordance with regulations. Depending on national regulations, gear unit components and/or add-on parts may have to be disposed of or given to recycling separately. 1 / 9BA 5

is incorporated in plant or machinery, the manufacturer of such plant or machinerymust ensure that the prescriptions, notes and descriptions contained in these instructions areincorporated in his own instructions. Removed safety equipment must be re-fitted prior to starting up. Notices attached to the gear unit, such as rating plate and direction arrow, must always be observed. They must be kept free from dirt and paint at all times. Missing plates must be replaced. Screws which have been damaged during assembly or disassembly work must be replaced with new ones of the same strength class and type. Spare parts must be obtained from Siemens (see section 1. "Spare parts, customer service"). 3.2 Environmental protection Dispose of any packaging material in accordance with regulations or separate it for recycling. When changing oil, the used oil must be collected in suitable containers. Remove any pools of oil immediately using an oil binding agent. Preservative agents should be stored separately from used oil. Used oil, preservative agents, oil binding agents and oil-soaked cloths must be disposed of in accordance with environmental legislation. Disposal of the gear unit after its useful life: Drain all the operating oil, preservative agent and/or cooling agent from the gear unit and dispose of in accordance with regulations. Depending on national regulations, gear unit components and/or add-on parts may have to be disposed of or given to recycling separately. 1 / 9BA 5| Model Type | Bevel-helical gear boxes B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1485.000000 |

| Ratio Range | 1 : 80…315 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 61600 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Siemens AG |

| Country of Manufacture | Belarus |

| Data Sheet & Drawings | Bevel-helical gear boxes B4 to Order code Article No LP Z Perm B4-FV-11B |