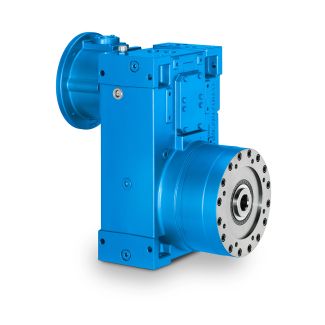

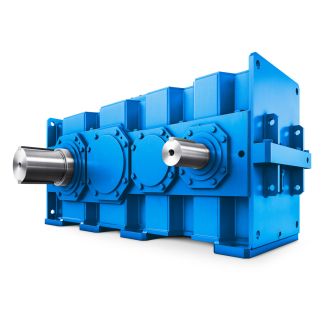

Bevel-helical gear units B4 Types B to B Dimensional drawings Type B Type BTyp B4-FH-13-D

In stock

SKU

B4-FH-13-D

$51,321.43

Flender/Flender Gear Units/Bevel-helical gear units B4

whereas that of hard wheat is very strong. Fig. 3 Hard wheat, soft wheat, and durum wheat. (Courtesy of the Canadian Grain Commission.) 3 Sarkar When viewed under microscope, soft wheat our appears woolly, whereas hard wheat our appears to

Canadian Grain Commission.) 3 Sarkar When viewed under microscope, soft wheat our appears woolly, whereas hard wheat our appears to  be hard and crystalline. These differences require somewhatdifferent approach for the preparation and milling of the soft wheat than that

be hard and crystalline. These differences require somewhatdifferent approach for the preparation and milling of the soft wheat than that  for hardwheat. 4.1 Preparation of Soft Wheat for Milling The principles of separation of all of the cleaning equipment is

for hardwheat. 4.1 Preparation of Soft Wheat for Milling The principles of separation of all of the cleaning equipment is  based on kernel size, shape, and density. Because soft wheat kernels are similar to hard wheat kernels relative to allof these characteristics, they are cleaned in the same manner as hard wheats. Tempering requirements for soft wheat are quite different and critical for achieving acceptable milling results. Soft wheat requires relatively lower milling moisture than hard wheat for easier and cleaner separation of bran. The texture of soft wheat kernelis soft relative to the texture of hard wheat kernel. Also the bran is relatively morepliable. Therefore, there is little or no risk of shredding the bran when milling soft wheatat lower moisture content. Additionally, the tempering time required for soft wheat isalso lower than hard wheat, for longer tempering time is required for mellowing the endo- sperm. The cell structure of the soft wheat being weak allows much quicker moisture penetration relative to the hard wheat. Lower levels of moisture addition in soft wheatalso is factor in reduced tempering time requirement. The average milling moisture ofsoft wheats is 1.0.0%. Tempering time varies from 4 to 1 . 4.2 Milling Milling of soft wheat requires lot more attention to detail than does the milling of hard wheat. This is because, being sticky in nature, the soft wheat ground material is hard tosift and separate. Thus, the milled products are not free-owing causing spouts, lifts, andother equipment to become easily plugged. In addition, when milling soft wheat, attenti

based on kernel size, shape, and density. Because soft wheat kernels are similar to hard wheat kernels relative to allof these characteristics, they are cleaned in the same manner as hard wheats. Tempering requirements for soft wheat are quite different and critical for achieving acceptable milling results. Soft wheat requires relatively lower milling moisture than hard wheat for easier and cleaner separation of bran. The texture of soft wheat kernelis soft relative to the texture of hard wheat kernel. Also the bran is relatively morepliable. Therefore, there is little or no risk of shredding the bran when milling soft wheatat lower moisture content. Additionally, the tempering time required for soft wheat isalso lower than hard wheat, for longer tempering time is required for mellowing the endo- sperm. The cell structure of the soft wheat being weak allows much quicker moisture penetration relative to the hard wheat. Lower levels of moisture addition in soft wheatalso is factor in reduced tempering time requirement. The average milling moisture ofsoft wheats is 1.0.0%. Tempering time varies from 4 to 1 . 4.2 Milling Milling of soft wheat requires lot more attention to detail than does the milling of hard wheat. This is because, being sticky in nature, the soft wheat ground material is hard tosift and separate. Thus, the milled products are not free-owing causing spouts, lifts, andother equipment to become easily plugged. In addition, when milling soft wheat, attenti| Model Type | Bevel-helical gear units B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 2395.000000 |

| Ratio Range | 1 : 80…315 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 90700 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | N.V. Flender Belge S.A. |

| Country of Manufacture | Moldova |

| Data Sheet & Drawings | Bevel-helical gear units B4 Types B to B Dimensional drawings Type B Type BTyp B4-FH-13-D |