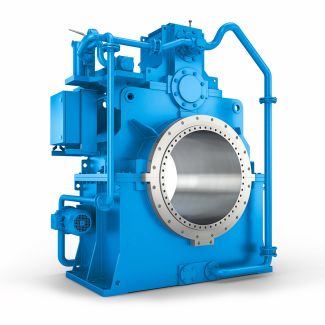

ne filter option for details see page The standa B4-DV-11-D Bevel-helical speed reduction gearbox B4

In stock

SKU

B4-DV-11-D

$31,821.43

Flender/Flender Gear Units/Bevel-helical speed reduction gearbox B4

uently loses three molecules of water to form furfural: 5H8O4 Pentosan/H1H2OHCl/ 2SO4 HeatC5H1O5 Pentose C5H4O2 Furfural/H1H 2O 8 Chakraverty The chemical reaction can also be presented as follows: CHO CHO CHOH /H2 CHOH CH /H1HOH CHOH /H2 CH 2OH Pentose

chemical reaction can also be presented as follows: CHO CHO CHOH /H2 CHOH CH /H1HOH CHOH /H2 CH 2OH Pentose  Furfural 6.3.2 Production Although corn oats are the main raw materials, bagasse, oat hulls, cottonseed hulls, and rice hulls are

Furfural 6.3.2 Production Although corn oats are the main raw materials, bagasse, oat hulls, cottonseed hulls, and rice hulls are  also used (. 6.3.3 Process In the past, crushed corncobs were treated with sulfuric acid at temperature of 1 1C

also used (. 6.3.3 Process In the past, crushed corncobs were treated with sulfuric acid at temperature of 1 1C  for 5 minutes. When corncobs were hydrolyzed with dilute sulfuric acid of 1.9% concentration at temperature of about 1 for 5 minutes, using solid/liquid ratio of 3:1, the yield of furfural was 9%. Subsequently number of methods havebeen developed for the production of furfural (. 6.4 Biodegradable Starch-Based Plastics Films The polysaccharides are abundantly available renewable sources, which can serve polymer needs in addition to their conventional applications. Starch is such natural polymer avail-able commercially at comparatively low price. Attempts have been made to use unmodi-ed starch directly in polymer systems. mixture of cornstarch, low-density polyethylene (LDPE), coupling agent, and urea is prepared. small amount of water is added to it so that starch is moistened enoughto smear itself uniformly around the granules of LDPE and the coupling agent. The com-pounded material is discharged in the form of continuous strand, which is cut with rotaryknives in granulator. The granules can be blown into smooth lm on the lm-blowingextruder. The tensile strength of these starch-based plastics lms is comparable to that of unmodied LDPE, whereas the elongation at break is reduced. The values for density,water absorption, and water-soluble matter are relatively higher in comparison with thoseof LDPE. Some of these lms are found to be biodegradable under the soil. Hence theselms can be used as carrier bags, agricultural mulch, and nursery bags (. Convers

for 5 minutes. When corncobs were hydrolyzed with dilute sulfuric acid of 1.9% concentration at temperature of about 1 for 5 minutes, using solid/liquid ratio of 3:1, the yield of furfural was 9%. Subsequently number of methods havebeen developed for the production of furfural (. 6.4 Biodegradable Starch-Based Plastics Films The polysaccharides are abundantly available renewable sources, which can serve polymer needs in addition to their conventional applications. Starch is such natural polymer avail-able commercially at comparatively low price. Attempts have been made to use unmodi-ed starch directly in polymer systems. mixture of cornstarch, low-density polyethylene (LDPE), coupling agent, and urea is prepared. small amount of water is added to it so that starch is moistened enoughto smear itself uniformly around the granules of LDPE and the coupling agent. The com-pounded material is discharged in the form of continuous strand, which is cut with rotaryknives in granulator. The granules can be blown into smooth lm on the lm-blowingextruder. The tensile strength of these starch-based plastics lms is comparable to that of unmodied LDPE, whereas the elongation at break is reduced. The values for density,water absorption, and water-soluble matter are relatively higher in comparison with thoseof LDPE. Some of these lms are found to be biodegradable under the soil. Hence theselms can be used as carrier bags, agricultural mulch, and nursery bags (. Convers| Model Type | Bevel-helical speed reduction gearbox B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1485.000000 |

| Ratio Range | 1 : 80…315 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 61600 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | A. Friedr. Flender AG & Co. KG |

| Country of Manufacture | San Marino |

| Data Sheet & Drawings | ne filter option for details see page The standa B4-DV-11-D Bevel-helical speed reduction gearbox B4 |