B4-DH-21B ial seal order via order code Y Side Radial shaf Bevel-helical gear reducer B4

In stock

SKU

B4-DH-21B

$197,142.86

Flender/Flender Gear Units/Bevel-helical gear reducer B4

type groat cutter is used to cut the groats into four pieces. These materials, con-sisting of small and large pieces, are sorted in small sifter as follows: 1. Large steel cuts 2. Regular steel cuts3. Small or baby steel cuts

are sorted in small sifter as follows: 1. Large steel cuts 2. Regular steel cuts3. Small or baby steel cuts  These steel cuts are passed through aking rolls in the aking system to produce variety of akes of different sizes

These steel cuts are passed through aking rolls in the aking system to produce variety of akes of different sizes  and properties. 3.3.1 Flaking Operation Flaking involves application of pressure or compression between two aking rolls to at- ten the

and properties. 3.3.1 Flaking Operation Flaking involves application of pressure or compression between two aking rolls to at- ten the  large groats or steel-cut groats into akes of desired thickness and property. Specialty Milling 3 The rolls are wear-resistant, and there is provision for maintaining desired opti- mum roll temperature through water cooling or preheating. The availability of roll pressureof 4 kN ensures formation of very thin akes if so desired. Here, the roll gapscan be varied accurately to provide akes of any desired thickness consistently. Thicknessaffects the cooking time. Whole groats or any steel-cutsized groats can be aked. Before aking, preparation of the material is essential. This preparation involves steaming in steamer, similar tothe one used before kiln drying. The addition of moisture and raising the temperatureallows the groats to become more tough and pliable and thus improve aking characteris-tics. This process also has benecial inuence on the nished product quality in terms offurther gelatinization of the starch. This improves not only digestibility, but also has other positive inuences on the functional and end use quality characteristics: namely, water absorption. The whole groats are aked into variety of old-fashioned rolled oats. Largesteel cuts are aked into quick rolled oats that require only 1 min to prepare. thicker version of the same, when processed through roll gap adjustment, may require about 3 min. After the aking operation, the rolled oats are dried and cooled in bed dryer. The drying target of the nished rolled oats is reduction to about 1.0% moisture. The products are packa

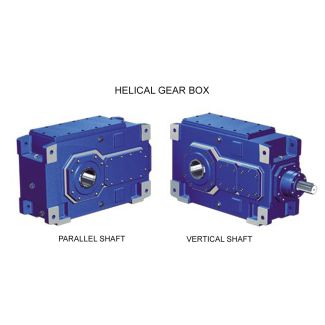

large groats or steel-cut groats into akes of desired thickness and property. Specialty Milling 3 The rolls are wear-resistant, and there is provision for maintaining desired opti- mum roll temperature through water cooling or preheating. The availability of roll pressureof 4 kN ensures formation of very thin akes if so desired. Here, the roll gapscan be varied accurately to provide akes of any desired thickness consistently. Thicknessaffects the cooking time. Whole groats or any steel-cutsized groats can be aked. Before aking, preparation of the material is essential. This preparation involves steaming in steamer, similar tothe one used before kiln drying. The addition of moisture and raising the temperatureallows the groats to become more tough and pliable and thus improve aking characteris-tics. This process also has benecial inuence on the nished product quality in terms offurther gelatinization of the starch. This improves not only digestibility, but also has other positive inuences on the functional and end use quality characteristics: namely, water absorption. The whole groats are aked into variety of old-fashioned rolled oats. Largesteel cuts are aked into quick rolled oats that require only 1 min to prepare. thicker version of the same, when processed through roll gap adjustment, may require about 3 min. After the aking operation, the rolled oats are dried and cooled in bed dryer. The drying target of the nished rolled oats is reduction to about 1.0% moisture. The products are packa| Model Type | Bevel-helical gear reducer B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 9200.000000 |

| Ratio Range | 1 : 80…315 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 420000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Singapore Pte. Ltd. |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | B4-DH-21B ial seal order via order code Y Side Radial shaf Bevel-helical gear reducer B4 |