ip DIN Hollow shaft Screw Dimensions in mm c c d B4-CV-13B Bevel-helical speed reduction gearbox B4

In stock

SKU

B4-CV-13B

$51,321.43

Flender/Flender Gear Units/Bevel-helical speed reduction gearbox B4

the required dimensions, then assigned variables or equations to corresponding feature dimensions during modeling. The model of gear unit consists of two sec tions: one is the fundamental shape, the dimensions of which are all given; the other is the

of two sec tions: one is the fundamental shape, the dimensions of which are all given; the other is the  external embellish, including the bosses around the axes, the oil gallery for lubrication, the inspecting hole and so on, the

external embellish, including the bosses around the axes, the oil gallery for lubrication, the inspecting hole and so on, the  dimensions of which are to be designed and determined by designers so as to create an ideal figu re of

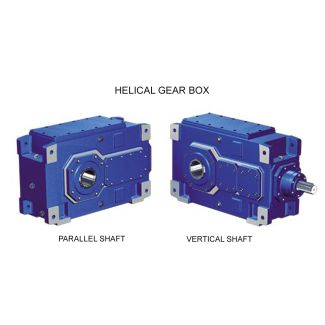

dimensions of which are to be designed and determined by designers so as to create an ideal figu re of  the case. Thus, each series of gear units merely requires single model, so that all parts in the entire series of gear units shall be generated through the family table and saved as an individual product respectively. The experimental results demonstrate that the development period is shortened, the cost is reduced and the productivity is increased. Keywords: Pro/Engineer, Gear Unit, Parametric Design, Family Table 1. Introduction Flender Co.Ltd is an enterprise named by German engineer called Flender, which has been purchased by SIEMENS automation group and become its new member. (Liang & Yu, 2, .. The major products of Flender Co.Ltd include gear units, gear motors, couplings, etc. Gear unit is one of the most remarkable products in this enterprise. Flenders gear units have all sort of structures such as vertical and horizontal. The transmission shafts are usually parallel or vertical. Th revolving speed is transmitted into the case by motor connected with flange and axis, then xported by solid or hollow shaft with key. Owing to its artistic appearance, convenient installation, low noise, large capacity and longevity, the Flenders gear unit has been widely applied to the industry of heavy assembly. This subject is to present method of parametric desi gn and modeling on large quantities of Flenders gear units using Pro/Engineer. Figure 1 shows 3-dimensional model of one sets gear units (completed). The gear unit . . /

the case. Thus, each series of gear units merely requires single model, so that all parts in the entire series of gear units shall be generated through the family table and saved as an individual product respectively. The experimental results demonstrate that the development period is shortened, the cost is reduced and the productivity is increased. Keywords: Pro/Engineer, Gear Unit, Parametric Design, Family Table 1. Introduction Flender Co.Ltd is an enterprise named by German engineer called Flender, which has been purchased by SIEMENS automation group and become its new member. (Liang & Yu, 2, .. The major products of Flender Co.Ltd include gear units, gear motors, couplings, etc. Gear unit is one of the most remarkable products in this enterprise. Flenders gear units have all sort of structures such as vertical and horizontal. The transmission shafts are usually parallel or vertical. Th revolving speed is transmitted into the case by motor connected with flange and axis, then xported by solid or hollow shaft with key. Owing to its artistic appearance, convenient installation, low noise, large capacity and longevity, the Flenders gear unit has been widely applied to the industry of heavy assembly. This subject is to present method of parametric desi gn and modeling on large quantities of Flenders gear units using Pro/Engineer. Figure 1 shows 3-dimensional model of one sets gear units (completed). The gear unit . . /| Model Type | Bevel-helical speed reduction gearbox B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 2395.000000 |

| Ratio Range | 1 : 80…315 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 90700 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Limited. |

| Country of Manufacture | Kyrgyzstan |

| Data Sheet & Drawings | ip DIN Hollow shaft Screw Dimensions in mm c c d B4-CV-13B Bevel-helical speed reduction gearbox B4 |