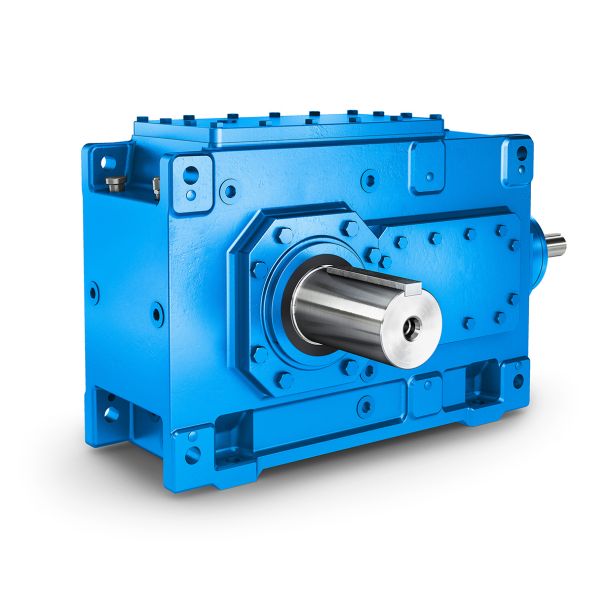

n is required For force application outside of cen B4-CH-12-A Bevel-helical gear box B4

In stock

SKU

B4-CH-12-A

$37,500.00

Flender/Flender Gear Units/Bevel-helical gear box B4

th two-stage planetary gearboxes of the Thyssen company. This concept gave rise to the Hydrodrive of the Mannesmann Rexroth company, where high speed hydraulic motors and three-stage planetary gearboxes were combined. similar installation was analysed in Mexi co 1 years

where high speed hydraulic motors and three-stage planetary gearboxes were combined. similar installation was analysed in Mexi co 1 years  later ( uoz and Lewinski, and important research about the torque distribu tion in three-roll sugar ills was carried out

later ( uoz and Lewinski, and important research about the torque distribu tion in three-roll sugar ills was carried out  in Australia (Kent and McKenzie, . In the 1s, Hgglunds developed higher torque hydraulic motors, allowing mill rolls to be

in Australia (Kent and McKenzie, . In the 1s, Hgglunds developed higher torque hydraulic motors, allowing mill rolls to be  driven individually, and eliminating the need for planetary gearboxes. Lewinski, . et al. Proc. Int. Soc. Sugar Cane Technol., Vol. 2, 2 ______________________________________________________________________________________ 2 At the same time, the German company Flende , well known manufact urer of gearboxes, presented Hydrex Planurex system, combini ng high torque hydraulic motor of their own manufacture and one-stage planetary gearbox. These high torque hydraulic motors, with and without planetary gearboxes, were very well received in the marketplace, due to the following advantages: 1. Partial or full elimination of onventional gears and crown gears. 2. Elimination of the tail bar. 3. Less space required. 4. Reduction of loads on roll shafts. 5. No foundation required. 6. Maximum torque over the full speed range; from zero to maximum speed. 7. Reversible movement. 8. Continuous speed variation in each roller. 9. Protection against overloading and almost immediate interruption of mill operation. 1. Simplifies automation of the milling process. 1. Measurement of the torque for each roller. 1. Easy maintenance. 1. Greatly reduced size and weight. 1. Power savings (high efficiency in transmi ssion, use of electric power, load reduction in journal bearings). 1. Increased extraction (optimisati on of the extraction process). The main advantage is the independen

driven individually, and eliminating the need for planetary gearboxes. Lewinski, . et al. Proc. Int. Soc. Sugar Cane Technol., Vol. 2, 2 ______________________________________________________________________________________ 2 At the same time, the German company Flende , well known manufact urer of gearboxes, presented Hydrex Planurex system, combini ng high torque hydraulic motor of their own manufacture and one-stage planetary gearbox. These high torque hydraulic motors, with and without planetary gearboxes, were very well received in the marketplace, due to the following advantages: 1. Partial or full elimination of onventional gears and crown gears. 2. Elimination of the tail bar. 3. Less space required. 4. Reduction of loads on roll shafts. 5. No foundation required. 6. Maximum torque over the full speed range; from zero to maximum speed. 7. Reversible movement. 8. Continuous speed variation in each roller. 9. Protection against overloading and almost immediate interruption of mill operation. 1. Simplifies automation of the milling process. 1. Measurement of the torque for each roller. 1. Easy maintenance. 1. Greatly reduced size and weight. 1. Power savings (high efficiency in transmi ssion, use of electric power, load reduction in journal bearings). 1. Increased extraction (optimisati on of the extraction process). The main advantage is the independen| Model Type | Bevel-helical gear box B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1750.000000 |

| Ratio Range | 1 : 100…400 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 78000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Brasil Ltda |

| Country of Manufacture | Tonga |

| Data Sheet & Drawings | n is required For force application outside of cen B4-CH-12-A Bevel-helical gear box B4 |