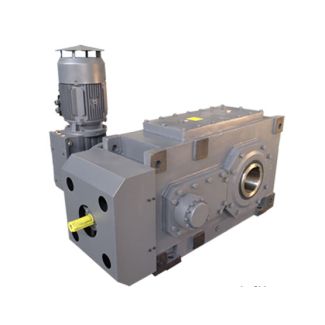

Bevel-helical gearboxes B3 ensions foursta ge gear unit sizes to Selectio B3SH-15-C

In stock

SKU

B3SH-15-C

$79,928.57

Flender/Flender Gear Units/Bevel-helical gearboxes B3

oaluminium because it offers industry greater production ca acity at lower coating costs. The development of process for electroaluminising bulk smarparts has also made major contribution in this context. The studies carried out within the framework of the & project

smarparts has also made major contribution in this context. The studies carried out within the framework of the & project  have led to the development ' of low-pollution processing steps which make the entire process for the electrodeposition of aluminium

have led to the development ' of low-pollution processing steps which make the entire process for the electrodeposition of aluminium  particularly gentle on the environment. This applies in particular to the use of lar- gely non-aqueous pretreatment process for the

particularly gentle on the environment. This applies in particular to the use of lar- gely non-aqueous pretreatment process for the  workpieces and to the avoidance of interme- diate coatings of copper or nickel for guaranteeing reliable adhesion of thealuminium coating to the substrate material. The anal ical determination of the alkyl complexes of aluminium dissolved in toluene, and the tant prerequisitesforthe successful, long-term use of the aproticaluminising electrolyte. In this wa , it was possible consistently to deposit aluminium coatings of perfect quality during sev- erayyears of operation under industrial conditions. Thus, it was also possible to electroplate large numbers of workpieces from all important branches of industry with superpure aluminium. These sample batches were subjected to all ma'or tests in industrial laboratories and to years of ractical trials, frequently in comparison witk cadmium coatings. In the meantime, several wetknown firms have approved the use of electroaluminium. This & project has thus made major contribution to the fact that low- ollution proces- sing technique - whose industrial importance will increase rapidly as soon as tEe required plant capacity is available to meet market demands - is now available for the electrodeposition of superpure aluminium coatings. targete dyt regeneration of the electrolyte by adding trialkylaluminium, have proven to be impor- 6 Duration: 0.0.8 - 3 0 9 0 ZH8 Subject: Development and testing of low-waste technolo ies for reduced pollution of the environment by electr

workpieces and to the avoidance of interme- diate coatings of copper or nickel for guaranteeing reliable adhesion of thealuminium coating to the substrate material. The anal ical determination of the alkyl complexes of aluminium dissolved in toluene, and the tant prerequisitesforthe successful, long-term use of the aproticaluminising electrolyte. In this wa , it was possible consistently to deposit aluminium coatings of perfect quality during sev- erayyears of operation under industrial conditions. Thus, it was also possible to electroplate large numbers of workpieces from all important branches of industry with superpure aluminium. These sample batches were subjected to all ma'or tests in industrial laboratories and to years of ractical trials, frequently in comparison witk cadmium coatings. In the meantime, several wetknown firms have approved the use of electroaluminium. This & project has thus made major contribution to the fact that low- ollution proces- sing technique - whose industrial importance will increase rapidly as soon as tEe required plant capacity is available to meet market demands - is now available for the electrodeposition of superpure aluminium coatings. targete dyt regeneration of the electrolyte by adding trialkylaluminium, have proven to be impor- 6 Duration: 0.0.8 - 3 0 9 0 ZH8 Subject: Development and testing of low-waste technolo ies for reduced pollution of the environment by electr| Model Type | Bevel-helical gearboxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 3730.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 153000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Guss Gmbh & Co. Kg |

| Country of Manufacture | China |

| Data Sheet & Drawings | Bevel-helical gearboxes B3 ensions foursta ge gear unit sizes to Selectio B3SH-15-C |