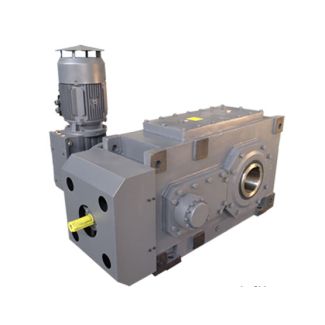

Bevel-helical gear boxes B3 n and ordering data continued Low speed shaft L B3-SH-15-D

In stock

SKU

B3-SH-15-D

$79,928.57

Flender/Flender Gear Units/Bevel-helical gear boxes B3

oard Grain-Grading Systems 4 and the overseas market. Similar conditions existed in southern Russia at the start of the 1th century, but the grading or handling system did not evolve, owing to social andtechnological factors. Wealthy landlords were major producers,

century, but the grading or handling system did not evolve, owing to social andtechnological factors. Wealthy landlords were major producers,  and the railways had notbeen introduced. Similar conditions existed in Argentina and Australia in the latter halfof the 1th century,

and the railways had notbeen introduced. Similar conditions existed in Argentina and Australia in the latter halfof the 1th century,  but failed to produce any new grain-handling methods. Canada, be- cause of increased production of wheat, evolved its grading system

but failed to produce any new grain-handling methods. Canada, be- cause of increased production of wheat, evolved its grading system  with legislation in 1 for grain-grading and handling. 2.1 Beginning of the United States-Grading System As the grain elds of the . . Midwest opened up, surplus production was moved by river, rail, or wagon to Chicago and Milwaukee for onward movement to Canada or the eastern seaboard of the . . and later to Europe. In 1 (Irvine, , the Chicago Board of Trade, followed by the Milwaukee Chamber of Commerce, established seriesof grades for wheat, based on cleanliness and bulk density to regulate the quality of wheaton the market. Club wheat: clean, 6 lb per Winchester bushel ( cylinder with diameter of 1.5 in. and depth of 8.0 in.) (7 kg/ No. 1 Spring: clean, 5 lb per Winchester bushel (7 kg/m No. 2 Spring: reasonably clean, 5 lb per Winchester bushel (6 kg/m Rejected: 4 lb per Winchester bushel (5 kg/m The proposed grades were for the trading community and there was no idea of compulsory grading of grains. The merchants paid fee to have their grain graded, andthis applied to grain coming into the Chicago market from other markets and also grain moving to markets outside of Chicago. 2.2 Origin of the Canadian-Grading System Wheat production in Ontario increased from 8,0 to 1.1 Mt annually from 1 to 1 (Irvine, . Most of the increase was in winter wheat and was due to many factors,such as an advancing frontier, large inow of immigrants to work the land and become producers, high prices, and good markets. The Crimean War of 1 improve

with legislation in 1 for grain-grading and handling. 2.1 Beginning of the United States-Grading System As the grain elds of the . . Midwest opened up, surplus production was moved by river, rail, or wagon to Chicago and Milwaukee for onward movement to Canada or the eastern seaboard of the . . and later to Europe. In 1 (Irvine, , the Chicago Board of Trade, followed by the Milwaukee Chamber of Commerce, established seriesof grades for wheat, based on cleanliness and bulk density to regulate the quality of wheaton the market. Club wheat: clean, 6 lb per Winchester bushel ( cylinder with diameter of 1.5 in. and depth of 8.0 in.) (7 kg/ No. 1 Spring: clean, 5 lb per Winchester bushel (7 kg/m No. 2 Spring: reasonably clean, 5 lb per Winchester bushel (6 kg/m Rejected: 4 lb per Winchester bushel (5 kg/m The proposed grades were for the trading community and there was no idea of compulsory grading of grains. The merchants paid fee to have their grain graded, andthis applied to grain coming into the Chicago market from other markets and also grain moving to markets outside of Chicago. 2.2 Origin of the Canadian-Grading System Wheat production in Ontario increased from 8,0 to 1.1 Mt annually from 1 to 1 (Irvine, . Most of the increase was in winter wheat and was due to many factors,such as an advancing frontier, large inow of immigrants to work the land and become producers, high prices, and good markets. The Crimean War of 1 improve| Model Type | Bevel-helical gear boxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 3730.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 153000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Industriegetriebe GmbH |

| Country of Manufacture | Tunisia |

| Data Sheet & Drawings | Bevel-helical gear boxes B3 n and ordering data continued Low speed shaft L B3-SH-15-D |