Bevel-helical speed reducer B3 ntinued Article No supplement th position Articl B3KV-9-C

In stock

SKU

B3KV-9-C

$19,285.71

Flender/Flender Gear Units/Bevel-helical speed reducer B3

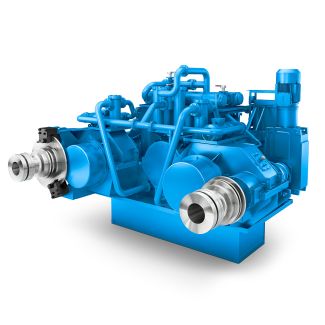

s 1.1 Noise measured in accordance with Directive 7/1 EEC 8LPA. RP2XD GENERAL ARRANGEMENT BASIC MACHINE RP2XD GENERAL ARRANGEMENT WITH LOADER OPERATING AND MAINTENANCE MANUAL SECTION 2 INSTALLATION AND OPERATING INSTRUCTIONS PRE-INSTALLATION On arrival of the equipment it is advisable

LOADER OPERATING AND MAINTENANCE MANUAL SECTION 2 INSTALLATION AND OPERATING INSTRUCTIONS PRE-INSTALLATION On arrival of the equipment it is advisable  to check that all packages listed on the consignment note have been received. The equipment must be offloaded using certified

to check that all packages listed on the consignment note have been received. The equipment must be offloaded using certified  lifting gear of suitable capacity, by competent person. When unloading the mixer, care must be taken to ensure the discharge

lifting gear of suitable capacity, by competent person. When unloading the mixer, care must be taken to ensure the discharge  chute remains clear of obstructions as the chute and door hang below the chassis. An outline drawing and bolt hold plan is normally sent prior to the despatch of the machine and will enable preparations to be made for the installation. Withthe `picture` of what the machine will look like when it is assembled, theancillary equipment dismantled for transport can easily be identified. INSTALLATION Please refer to contract arrangement and site instructions as applicable. It is recommended that concrete foundation of at least 0.6m square by 0.3m thick (to take M2foundation bolts not supplied) should be provided for eachleg of the support structure and runway when fitted. When the machine issupplied without support structure it should be mounted on supports ofsufficient strength and rigidity to prevent undue vibration when the machine isworking. When making provision for loading hopper pit it is stronglyrecommended that the pit is concreted out so that it can easily be kept clean andfree from any build up which could prevent the bottom limit switch fromoperating correctly. Before completing the installation, check that the main mixer frame is level with spirit level. Packings should be inserted as required under the structurelegs or main frame. The packings under the mixing pan roller brackets are setduring manufacturing and must not be disturbed under any circumstances. Check that the pan is seated and that the pan rack and drive ge

chute remains clear of obstructions as the chute and door hang below the chassis. An outline drawing and bolt hold plan is normally sent prior to the despatch of the machine and will enable preparations to be made for the installation. Withthe `picture` of what the machine will look like when it is assembled, theancillary equipment dismantled for transport can easily be identified. INSTALLATION Please refer to contract arrangement and site instructions as applicable. It is recommended that concrete foundation of at least 0.6m square by 0.3m thick (to take M2foundation bolts not supplied) should be provided for eachleg of the support structure and runway when fitted. When the machine issupplied without support structure it should be mounted on supports ofsufficient strength and rigidity to prevent undue vibration when the machine isworking. When making provision for loading hopper pit it is stronglyrecommended that the pit is concreted out so that it can easily be kept clean andfree from any build up which could prevent the bottom limit switch fromoperating correctly. Before completing the installation, check that the main mixer frame is level with spirit level. Packings should be inserted as required under the structurelegs or main frame. The packings under the mixing pan roller brackets are setduring manufacturing and must not be disturbed under any circumstances. Check that the pan is seated and that the pan rack and drive ge| Model Type | Bevel-helical speed reducer B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 900.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 35700 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Ges.m.b.H. |

| Country of Manufacture | North Macedonia |

| Data Sheet & Drawings | Bevel-helical speed reducer B3 ntinued Article No supplement th position Articl B3KV-9-C |